Gravimatic® – the new generation of fully

automated concrete spreading

Since 1987, the automatic concrete spreaders developed by Weckenmann have been offering decisive advantages for the manufacturers of two-dimensional precast concrete elements. In addition to a concreting process which does not require operators to a large extent, mainly producers of relatively thin-walled mass products like floor slabs or double walls benefit from the exact dosing of quantity of this system. Therefore, today it is state of the art in many modern precast concrete element plants.

Depending on the user it was possible to save an amount of concrete of up to 15% of the applied concrete. This resulted in an amortization of the newly invested concrete spreading system already within 1-2 years.

The first generation of the automatically operating concrete spreader transfers the geometric data of the concrete element in a travelling program via CAD/CAM control and puts the correct quantity of concrete into the formwork with a high accuracy (less than 5% deviation to the target weight). The control system determines the individual volume requirement of concrete of the respective element, converts it into weight units and compares this value to the concrete discharge, which is measured via the change of weight of the concrete container. The concrete container is mounted to weight load cells and continuously reports the current container content to the control system.

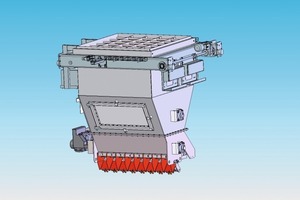

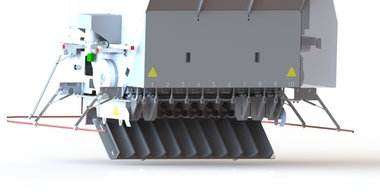

This system is compatible with all common dosing principles used by Weckenmann according to requirement and customer request. This includes spiked rollers with sliders, screw systems and also belt conveyors. Weckenmann favors spiked rollers dosing because of the following advantages:

Wide range of consistency of the workable concretes

Low wear

Container is (concrete) tight if the sliders are closed

Fast to clean

Less sealing points, i.e. less maintenance and spare part consumption

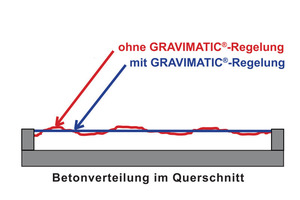

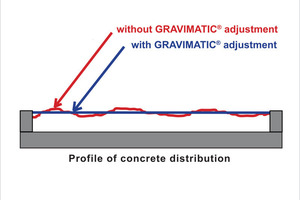

All these conveying systems have one thing in common: It is difficult to achieve a completely constant flow of concrete. The reasons for this are manifold and range from a possible inhomogeneity of the concrete which cannot be avoided completely, via insufficient mixing, to longer standing times of the concrete in the container up to change of consistency in case of different aggregate moisture. The wider the design of the container, i.e. the more dosing systems are arranged next to each other, the higher is the risk that the concrete discharge becomes uneven along the width. This results in the fact, that the goal of the exact quantity dosing via the automatic concrete spreader can be guaranteed, but not in all cases the exact distribution of the concrete quantity within the geometry of the precast parts. This might require manual finishing works.

If the generated concrete layer is followed by another process step it is extremely important to adhere to the thickness tolerances. This includes for example the production of high-quality architectural concrete facades, where concrete recipes which were produced in a costly manner should be used in a possibly economic way, or if, in case of sandwich panels, insulating material is applied and a precisely even concrete structure is required. The following calculation example illustrates the possible savings with a dosing and distribution of the concrete which can be exactly adjusted.

Assumptions:

Producer of high-quality facades with architectural concrete surface (annual performance 20,000m²)

Use of face concrete with corresponding additions (concrete costs 200 €/m³)

Concrete consumption per year with a target thickness of 60 mm: 1,200 m³

Improvement of concrete consumption at least 10%

Possible savings (1,200 m³ x 200 €/m³ x 10%): 24,000 €/year

Weckenmann has been working on an improvement of automated and adjustable dosing of fresh concrete for several years. After an extensive elaboration of the basis, developments and tests with a prototype system which was specifically installed for this purpose, the patent-granted concept of Gravimatic is now ready for the market and can be used for various discharge systems, such as spiked rollers, screw systems or belt conveyors.

Gravimatic by Weckenmann enables continuous measurement of the discharge volume of single discharge elements (slider, screw or belt conveyor section). In this way the respective discharge element is automatically readjusted, which results in homogeneous concrete discharge. Gravimatic enables a higher productivity gain with minimum amortisation periods and in general it is also possible to retrofit existing concrete spreaders with it. It must be checked in each case if retrofitting can be implemented with a reasonable effort.

Conclusion

Gravimatic is a unique automation solution for powerful two-dimensional concrete spreaders because it offers constant flow control at all single discharge elements of a concrete spreader. The user can benefit from the following advantages:

Reduction of concrete consumption by 10% and more

Saving of manual spreading work

Increased product quality due to layer thicknesses which are precisely adhered to

Acceleration of working processes

Prevention of concrete waste

Retrofitting of existing concrete spreaders is possible

The Gravimatic solution is suitable for new as well as for the modernisation of existing installations and is adapted in engineering terms to the individual requirements.