The Warsaw Stadium:

Solutions for expansion and reinforcement

A new landmark was added to the Polish capital during a construction period of almost four years: the "Stadion Narodowy w Warszawie", or Warsaw National Stadium. This stadium was built specifically for the UEFA Euro 2012. Although largely invisible, products provided by the Berlin-based fastening and reinforcement supplier Deutsche Kahneisen Gesellschaft mbH played a major role in the construction phase.

The award of the UEFA Euro 2012 to Poland and Ukraine resulted in major challenges regarding the extension and upgrade of the infrastructure in both countries. For example, only some soccer league stadiums were previously located in the Polish capital; these were, however, too small to meet the requirements of such an event. In addition, Warsaw featured an athletics arena built in 1955, which, in recent years, has been used as the venue for a weekly market. Against this background, the construction of a new stadium was inevitable.

Soccer on top of the underground car park

The client, the NationalSports Center, awarded the design of the new stadium to architects Mariusz Rutz und Zbigniew Pszczólny, of J.S.K Architekten in Düsseldorf. German architects GMP and SBP were also commissioned. The 400 million euro project was constructed by a consortium of contractors led by Alpine Bau Deutschland AG.

Besides the actual stadium sitting on the bank of Wisla river, the design brief also included offices, conference rooms, physiotherapists‘ practices and restaurants, as well as one of the largest underground car parks in Poland providing 1,700 lots arranged on two levels underneath the pitch. The stadium sits on a foundation composed of 14,000 reinforced concrete piles due to the geology of the site. The appearance of the eight-story precast reinforced concrete structure on top is akin to a giant willow basket adorned with the Polish national colors. It provides about 58,000 seats.

The stadium‘s most prominent feature is its suspended steel roof covering an area of 55,000 m2. A 10,000 m2 segment of the roof can be opened. Its closing mechanism makes it possible to hold sports and cultural events even under adverse weather conditions.

A positively fitting solution

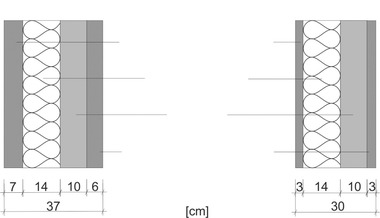

Due to its dimensions with a total floor space of more than 200,000 m2 (130,000 m2 of which underground), the stadium includes a large number of structural expansion joints to ensure the transfer of considerable shear loads. This target was achieved by using a reliable solution composed of the Johrdahl JDSD and JDSDQ double shear connectors. Overall, more than 6,000 Jordahl shear connectors (from JDSD 25 HF to JDSD 120 HF) were inserted in the structure.

If the JDSD design is used, the pair of connectors may move in longitudinal direction within the sliding tube in order to enable the necessary expansion of the structural element. Double shear connectors are preferably used in expansion joints of large slabs. They establish a positive locking between shear walls and load-bearing walls, for abutments and angular walls.

This connector type is available in various standard dimensions. It can resist design loads of up to 996.5 kN and may be used for gap widths of up to 60 mm. Due to its particular tube shape, the JDSDQ connector also resists transverse shear forces and torsional loads. It is designed for loads of up to 896.8 kN and gap widths of up to 60 mm. This connector type is frequently used in areas subject to biaxial strain.

Structures that usually require double supports can alternatively be fitted with double shear connectors. Floor abutments need no longer include a bracket.

Carefully selected materials – long service lives

Jordahl double shear connectors have been successfully used for several decades. The related National Technical Approval was granted under No. Z-15.7-237. Development and production conform to the DIN EN ISO 9001-2008 specifications. Double shear connectors can resist very high loads due to their rigid design. They are only subject to minor deformation and thus prevent explosive effects in the concrete.

The ultra-precise manufacturing process used for Jordahl double shear connectors provides greatest flexibility whilst ensuring a uniform transmission of forces to the two connectors. The efficient lubrication between the round connector and the sliding tube and the uniform load distribution across the two connectors result in low sliding pressure friction. The connectors are easy to install in an economical process. Nonetheless, they later ensure reliable, accurate linear guidance or level support.

All parts used in Jordahl double shear connectors are made of high-strength stainless steel (grades 1.4462 and 1.4571). These materials conform to corrosion resistance class III or IV as specified in National Technical Approval No. Z-30.3-6. No additional anti-corrosion treatment is necessary, even when exposed to high amounts of chloride or used in sea water or aggressive industrial environments.

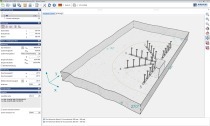

Jordahl provides its customers with a free, easy-to-use software for designing and selecting the type of double shear connector best suited to the specific project needs.

Rapid rearrangement of seats

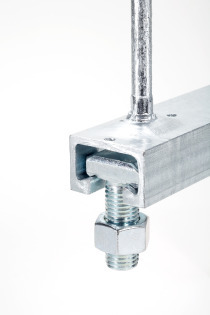

The stadium grandstands of the Warsaw National Stadium consist of over 2,000 precast components, which have been connected to each other by anchor channels and mounting brackets. This design ensured the quick completion of the grandstands. Anchor channels were also used for fixing the seats. The seats need to be rearranged as required for various types of events, which is why they need to be quick and easy to assemble and disassemble. For this reason, 5,200 Jordahl JTA W40/22 anchor channels and JC T-bolts were used for fastening the seats to the precast grandstand components. These anchor channels were granted a European Technical Approval (ETA-09/0338). The transitions between precast concrete and masonry were created using Jordahl anchor channels and JMA wall junction anchors.

At the reinforced concrete structural design stage, the team of structural designers closely collaborated with the specialists of the Polish Jordahl subsidiary, Jordahl & Pfeifer Technika Budowlana Sp. z. o. o. located in Krepice. Structural designer Miłosław Matejko praises the excellent technical support provided by the subsidiary staff. „The engineers pro-actively supported the design team regarding the selection of suitable shear connectors but also trained the employees of the reinforced concrete construction contractor when it came to the appropriate insertion of the double shear connectors in the structural components of the stadium,“ says Matejko.