3D-scan technology for a perfect batching plant

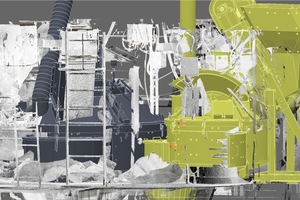

“In planning a modification or expansion of your batching plant we leave nothing to chance and we are not wasting any millimeter of space. With the Pemat 3D- scan technology, we scan the inside and outside of your plant in all details so we can rebuild it on the computer. Your future plant will be created in the virtual reality, that way you can inspect and test it - before even the modification has begun”, says Christian Filsinger, Head of Technology & Sales at Pemat Mischtechnik GmbH.

The Lintel Group, based in Rheda-Wiedenbrück and with five locations in eastern and southeastern Westphalia, is a competent partner for home and garden.

Developing products from the highest quality raw materials and with uncompromising quality is a matter of course.

Pilot project for several successful batching plant modernization

Because it‘s all about making good things better, they decided to invest in mixing technology at different locations. Since these are modification measures and the new mixing technology had to be integrated into existing systems, Pemat was able to convince Lintel to implement the project (presented at Bauma 2019) with the help of a 3D-Scan - Realize.ING.

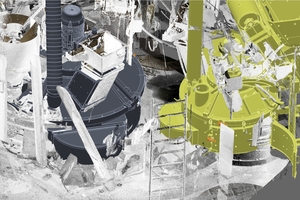

Paderborn was selected as the first location. There, two existing mixers and one skip hoist were replaced.

Pemat supplied two new Planetary Mixers PMP 1875 and PMPR 750 and a new PAS 750 skip hoist to improve and ensure product quality. Furthermore, various modifications were made by Lintel.

This project was the starting signal for several successful modernizations of batching plants, and further editorial contributions on this topic follow.