3D printing of large elements on the construction site

Putzmeister Engineering GmbH, Ed. Züblin AG and HeidelbergCement AG have formed the cross-sector 3D@Site consortium, joining forces to make 3D printing suitable for use on the construction site. For this purpose, the concrete pump is to be converted into a printer that will be supplied with printable ready-mixed concrete on site. The research project is based on the TU Dresden initiated CONPrint3D project, in which Putzmeister was already involved. The structural elements are to be printed directly from the BIM model, meaning that information on the building must be processed so as to generate production data for the printer.

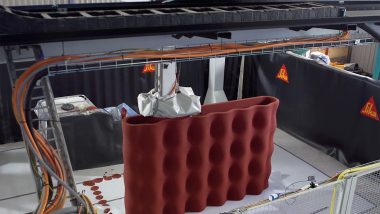

HeidelbergCement is responsible for developing a concrete suitable for the 3D printing process. The particular challenge here is that the concrete needs to be suitable for pumping and printing at the same time. Concretes with thixotropic properties have proven to be particularly suitable for this purpose. The very early strength of the printing concrete is controlled by means of additives. In addition, the focus is on the cost-efficiency and sustainability of the printing concrete, which is achieved, for example, by using a maximum particle size of 16 mm and cements with reduced clinker content. To realize the goal of printing a reinforced wall, cut-outs for steel reinforcing bars are provided in the concrete element, which will be subsequently completed and grouted. The reinforcement design is drawn up by Züblin and is based on the previously tested concept of “zone-reinforced walls”. Printing of a first reinforced wall element as a prototype is scheduled for 2020.