$752,000 for Solidia Research into Utilization of CO2

The next phase of a four-year research and development project supporting the commercialization of Solidia Technologies carbon dioxide-reducing cement and concrete processes will commence with the commitment of an additional $752,000 from the US Department of Energy‘s National Energy Technology Laboratory (NETL).

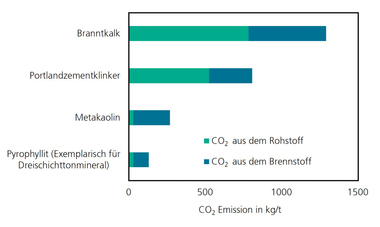

The project entitled „Utilization of CO2 in High Performance Building and Infrastructure Products“ is co-funded by NETL through its Carbon Storage Technology program, and by Solidia Technologies. The overall goal is to use an alternative to ordinary Portland cement (OPC) to produce a...