Enlightenment with Northern Lights – storage of CO2 below the seabed

Although knowledge of CO2 storage below the seabed is not entirely new, many do not know how such storage can function and/or are rather skeptical of the whole idea. But there is no getting around the topic itself, and the concrete associations of the German state of Baden-Württemberg would like to bring light into the darkness by answering some questions.

When, around the 1700s, the focus was initially on creating acceptance for newly obtained knowledge and on overcoming, through rational thinking, all structures that hinder progress. Although knowledge of the storage of CO2 below the seabed is not entirely new, many still do not know how such storage can function or are skeptical about the whole thing. However, there is no avoiding the topic itself, since in view of the European Green Deal and the responsibility towards the environment and future generations, all options for dealing with the emission of CO2 must be thought through. And there is little time left before the targeted climate neutrality by 2045.

The concrete associations of the German state of Baden-Württemberg would like to bring light into the darkness by answering some questions.

Why is the storage below the seabed of such interest for cement and concrete plants?

Among many other segments of industry, the cement and the concrete industries are in the middle of transformation toward becoming climate-neutral sectors. This not only includes continued development of cements and concretes and their manufacture with the aid of new formulas and AI, but also includes carbon-capture technologies that can capture a major part of process-related CO2 emission during cement manufacture.

At cement plants, CO2 can be captured and liquefied. If a way is found to store CO2 in its natural state in sandstone layers, negative emissions are generated that will help the cement industry on the way to climate neutrality.

Since the process-related emission of CO2 in cement production accounts for a major part of the CO2 footprint in concrete, use of this technological progress would also support the concrete and concrete production industry on its way to CO2 neutrality.

Prof. Dr. Klaus Wallmann, head of the research unit Geomar Helmholtz Center for Ocean Research in Kiel, has been conducting research on this topic for many years. According to him, there are no large cavities available in the sandstone formations of the North Sea.

How does the storage of CO2 below the seabed function?

The geological situation of interest here is, rather, the presence of microscopically small pore spaces between the individual sand grains into which CO2 can be stored. In other words: CO2 can be deposited into deep sandstone layers from which oil and also gas has already been extracted. Suitable storage sites are porous sandstone layers topped by impermeable layers of clay that can sustain the high pressure at which the CO2 is pressed into the rock below.

Are there models for this?

Denmark has been storing CO2 in the Danish North Sea within the scope of the Greensand CO2 project since the spring of 2023. In a former oil field, around 200 km off the coast, up to 13 million tons of carbon dioxide are planned to be stored in the North Sea.

Norway does the same as early as 2015, with the Sleipner project, in collaboration with the US National Energy Technology Laboratory (NETL) and the US Department of Energy (DOE). The Sleipner project was started in 1996 as the world’s first large-scale CO2 storage project by Statoil (now Equinor) and its partners on the Sleipner gas field in the North Sea off the Norwegian coast. Sleipner continues to be the world’s longest-running CO2 storage project. There, around 1 million tons of CO2 are injected annually into the saline Utsira Formation through a single wellhole. The Utsira Formation is a massive sandstone formation up to 300 m deep that is capable of storing an estimated 600 billion tons of CO2.

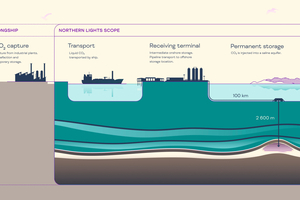

Since March of 2021, major efforts are being made to promote this technology off the cost of Norway with the Northern Lights project, in partnership with Equinor, Shell and TotalEnergies, and to develop the infrastructure needed in Norway.

The first phase of developing a storage capacity of 1.5 million tons of CO2 annually is part of the Longship project. This project was initiated by the Norwegian government and was aimed at developing a comprehensive CCS (Carbon Capture and Storage) value-added chain in Norway.

The Northern Lights project and the Longship project were already presented, among other events, at the BetonTage 2023 (www.betontage.de), where Norway was the guest country. In this context, reference was also made to the new Norcem plant in Brevik in Norway, which is a subsidy of the German construction materials group and cement manufacturer Heidelberg Materials. From there, beginning in October 2024, the first carbon dioxide will be delivered by special ship to the terminal in Øygarden near Bergen, from which pipelines lead into the seabed of the North Sea. A total of 400,000 tons of CO2, nearly one per cement of Norway’s current emissions, are planned to be captured alone in the cement plant in Brevik and stored underground.

Norcem is part of the Longship project of the Norwegian government. The Norwegian state assumes the major share of the costs needed to build the capture facility in the plant in Brevik. Northern Lights will assume transport and storage of the CO2 from Heidelberg Materials.

Are there risks?

Yes and no: There exist around 15,000 wellholes in the North Sea and, according to Wallmann, there is an increased risk of leakages near old wellholes. From these holes, CO2 escapes with great probability. Even if this occurs, however, the risk to the environment is relatively small: in such cases, damage to the eco system may occur in smaller areas, locally limited to approx. 50 m². The decline of biological diversity will accordingly occur in only very small areas.

According to Wallmann, the German seabed is not drilled to such an extent, since hardly any oil and gas are extracted there. In his opinion, a search for other options should first take place and, if implemented, closely observed and regulated.

For safe storage of CO2 in deeper geological layers, however, the US National Energy Technology Laboratory (NETL), which collaborates with Equinor, speak for

(1) Nearly five decades of experience in the oil and gas industry, with injection of CO2 in oil- and gas-filled formations;

(2) Twenty-year technological advancements achieved with programs such as the program of the U.S. Department of Energy with carbon;

(3) Field test campaigns such as the Regional Carbon Sequestration Partnerships (RCSPs), which validate the monitoring tools and strategies that have developed the best practices;

(4) A better understanding of the physical, chemical and mechanical engineering that plays a role during the entire lifespan of a CCUS project, and that served as basis for new tools for risk assessment and risk management; and

(5) The growing number of CCUS demonstration and commercial projects worldwide, which promote learning by doing.

(Source: NETL Executive Report – Safe Geologic Storage of Captured Carbon Dioxide)

The seismic 3D-monitoring of CO2 injection into the Utsira Formation in the period from June 2015 to September 2016, performed in the Sleipner project, showed that CO2 at least does not escape into other horizons.

Political situation in Germany

As early as ten years ago, the German black-yellow coalition of that day attempted to implement CO2 storage in Germany. The current German Federal Minister for Economic Affairs was at that time against storage. Today, the Federal Ministry for Economic Affairs and Climate Action, calls CCUS a “building block for a climate-neutral and competitive industry” and is working currently on a carbon management strategy to deal with residual emissions that are difficult or impossible to eliminate.

A stakeholder dialog with representatives of civil society, science and economics began in March of 2023. The German Energy Agency, dena, moderated the exchange and passed on the following recommendations to the German Federal Government:

CCS should be admitted for the industrial sectors in which CO₂ is unavoidable (e.g., lime and cement);

CCS should also be admitted for the chemical industry, at least as a gap technology (e.g., steel, chemistry, glass);

CCS should be forbidden for the energy sector – as well as for sectors in which alternatives exists (e.g., electrification);

If possible, the technology should be used in such a way that negative emissions are generated;

The resulting CO₂ should, if possible, be exported for storage. In Germany, CO₂ storage is rejected by environmental organizations. But capacities for storage in Germany should nevertheless be investigated.”

(Source: Frankfurter Rundschau)

Necessary fields of application of CCU and CCS technologies as well as the question of where storage could take place, should be examined within the scope of the Carbon Management Strategy.

According to the German daily Frankfurter Rundschau, the law based on the recommendations and the prepared Carbon Management Strategy of the Federal Government could be adopted as early as the first half of 2024.

CO2 infrastructure in Germany

For transport of CO2 in Germany, three primary transport routes are available: rail, ship and pipeline. Due to the CO2 emission of trucks, transport by road can be an option only in the rarest cases.

For longer distances, according to the Fraunhofer Institute for System and Innovation Research (ISI), onshore and offshore pipelines as well as transport by ship are feasible options. For the latter, transport ships similar to those used for transport of liquid gas could therefore be employed; their transport capacity, moreover, is significantly greater than that of trains. Most of the container-based or existing pipeline-based transport solutions could be repurposed for CO2 transport without major problems; transport of CO2, according to Fraunhofer ISI, does not represent a technological challenge.

The actual challenge, according to the magazine beton is the current state of the art with respect to the required points of transfer for pure filling or discharge – which still operate too slowly. As for rail transport, there moreover exists no uniform standard for couplings and connections for loading and unloading of the rail cars.

Furthermore, according to the above-stated publication, there is yet no uniform specifications for pipelines for the composition of the CO2 to be transported. These specifications, however, are necessary since the quality of the steel and its thickness are subject to strict safety criteria, and corrosion on the inside must be prevented.

In Germany, the first completely decarbonized cement plant within the scope of the GeZero Carbon Capture and Storage (CCS) project by Heidelberg Materials in Geseke is scheduled for completion in 2029. There, the first complete CCS value-added chain for capture, transport and durable storage of all CO2 emissions within Germany will be realized. The facility is designed for capturing around 700,000 tons of CO2 annually.

In Germany, Open Grid Europe GmbH (OGE) currently plans a pipeline operation for exporting CO. The company has already built, until the end of 2022, the WAL pipeline, for the LNG terminal in Wilhelmshaven, as an alternative to Russian gas. The planned OGE CO2 transport network consists of the OGE projects WHVCO2logne, the Delta Rhine Corridor and the Elbmündung und Rheinisches Revier clusters. The aim, according to the company, is the rapid development of export options in Wilhelmshaven, Rotterdam and Antwerp/Zeebrugge.

The initial network is planned to extend over a length of more than 960 km and would enable the transport of 18.8 million tons of CO2 annually. OGLE currently proceeds on the assumption of a complete newbuild of the infrastructure and would like to develop both the projects and the clusters as well as the CO2 transport network flexibly in accordance with transport requirements.

It would, for example, like to connect locations where CO2 is captured – such as in the cement and limestone industry – with locations where CO2 is used – such as in the chemical industry. In addition, connections of locations where CO2 is captured at relevant port locations, such as Wilhelmshaven, are envisioned. A map with the transport network planned already exists and is available on the company’s website (https://oge.net/de/co2/co2-netz).