A success, train after train

The newly built Ebensfeld-Erfurt line is designed for a maximum speed of 300 km/h. The components of the FF Bögl system from Max Bögl that are installed there combine cost effectiveness, long life cycles, and operational safety.

The new Ebensfeld-Erfurt line, part of the high-speed line from Berlin to Munich, was implemented as part of the German Unification Transport Project VDE 8. It is designed for passenger and freight service with a maximum speed of up to 300 km/h.

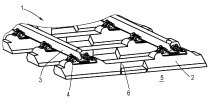

For upgrading the 32-km, double-track segment between the Erfurt rail junction and the newly erected Ilmtal Bridge near Langewiesen, the entire product portfolio of the FF Bögl system for high-speed railway systems from Max Bögl came into play. These products include standard track-supporting slabs, special-purpose slabs, slab systems that can support wheeled vehicle traffic in tunnels, as well as switch-support slabs and noise abatement walls used in Germany for the first time.

Proven standard system

Construction of the new line section began in September of 2010. Major challenges faced the Max Bögl Group in planning and implementing the track section. These included grade and embankment track and civil-engineering structures completed during 2000 and 2005 in close cooperation with the relevant departments of Deutsche Bahn AG. This work entailed upgrading of constructed track and structures in accordance with the current body of regulations and/or to adapt them to the internationally proven FF Bögl system.

Following reconditioning and re-profiling of major sections of the already existing frost-protection layer and after installation of the hydraulically bound support layer, laying of the first track-supporting slabs started in August of 2011. The slabs that were prefabricated in the Sengenthal precast plant were transported by rail to the Arnstadt freight yard, were they were transferred to trucks and transported to the construction site. To optimize service to and at the construction site, the route was subdivided into eleven sub-sections. Installation of the around 8,800 track-supporting slabs was completed in June of 2013.

Special applications for bridge and tunnel slabs

Between Ilmenau and Erfurt, the North Project Stage of the new section crosses also the three twin-tube tunnels Sandberg, Behringen, and Augustaburg. In these areas, special precast parts were installed, as well as in-situ stationary surface elements cast alongside and between the tracks. This will enable emergency crews to safely drive through the tunnel with wheeled vehicles; they serve, in addition, for derailment protection.

On the bridges, whose unfinished structure had been completed many years ago – nine of twelve structures are categorized as “long bridges” with effective lengths of more than 25 m – special slabs were used of the type previously installed on the Nuremberg–Ingolstadt line. For these longer bridge structures, the FF Bögl system was implemented, applying the HFFBrü construction method (instructions for installation on slab track systems on bridge), as defined in Deutsche Bahn master planning. On bridge lengths of approx. 2,700 m, around 1,200 of these special bridge slabs were used, with integrated stoppers on the underside to ensure positional security.

German premiere for switch-support slabs

At the overtaking stations Eischleben and Ilmenau-Wolfsberg, and for the first time in Germany, all of the switches in the continuous main track – eight turnout switches and twelve track connection switches – were installed with WTB prefabricated switch-support slabs with the FF Bögl system. This high-precision rail line, implemented with CNC technology for high-speed switches had already been previously used years before on the Chinese high-speed Beijing-Tianjin, Wuhan-Guangzhou, and Beijing-Shanghai lines and has also been approved in Germany since 2007.