BIM and digitalization: how to convert these challenges in great chances for precast concrete industry

Nearly any individual or collective activity, business or personal one, and in almost anywhere in the world, requires a growing technological component (connectivity, mobile and apps use, internet of things, use of drones, etc.) However, the construction sector is one of the least in which technology has been introduced, especially if we focus it in its execution stage, which is usually carried out in a dynamic environment and with a high level of uncertainty.

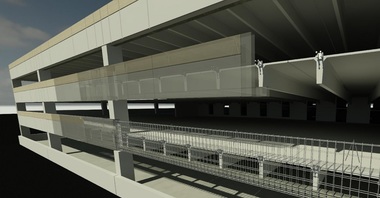

Against this model of action, products and systems manufactured in an industrial plant have a higher technical potential of automation, much more predictable tasks, with previously defined personnel and machinery, with greater experience effect and which are based on the systematic repetition of instructions, rules and calculations.

Industry 4.0 does not only automate some of the construction activities, it allows to improve the communication of the agents involved in it, improve the design of the processes and make decisions based on real data and simulations made from digital models. All this causes that the construction works to be made on site are more difficult to automate and, therefore, new digital technologies are fundamentally aimed at theindustrialization of certain construction processes, achieving greater efficiency and quality, without the finished work losing uniqueness and capacity to adapt to the place where it is located, so we have such a great opportunity for unprecedented development. In this respect, prefabrication as a variant of industrialized concrete construction, is based on anticipating the factory, a much more controlled, planned and automated environment than the work itself, as many production processes as possible, so it is almost inevitable that the use of digitization will provide an additional impetus to consolidate all the advantages it brings - less waste, durability, optimized sections, less dependence on available on-site workforce, work safety, etc. - and further improve the efficiency in the design, manufacture or logistics of precast elements, as opposed to on-site construction.

At the core of this technological evolution is found the BIM methodology, which consists in the creation of digital models of the project, whether a building or an infrastructure, through increasingly advanced software that allow to share these models among the different agents involved: architecture and engineering, builders, developers and suppliers. As it happens in prefabrication, BIM is based on setting a accurate and unequivocal definition of each construction component, ensuring geometric and spatial precision in such a way that errors that are normally emerged during the execution due to deviations or unforeseen events are minimized, which have unpredictable damage and that are especially inherent to the traditional construction being fundamentally conditioned to the good or poor execution of the on-site workforce, but that in the case of precast concrete must be avoided from the early design phase in order to guarantee the correct assembly among the different elements. Furthermore, the use of BIM coupled with the industrialized construction, brings efficiency to the construction process by allowing to test in the digital model some aspects such as the performance of the design (for example, essential characteristics of the corresponding harmonized standard, or environmental impacts coming from the Environmental Product Declarations), the precision of the assembly planning or the quantity of materials required.

At the same time, another technological developments are progressing specially aimed at the manufacture of building elements - use of embedded sensors, autonomous or collaborative robots, augmented reality, 3D printing, data management programs, etc. - that can further help to improve the overall efficiency of the precast concrete industry.

ANDECE has been decisively committed to adapt as industry to this necessary technological transformation for the last decade, in order to guide its member companies to implement and the maximum profit of these different ways of digitization that the market puts at our disposal, with the maximum aim of improving our competitiveness and presenting us as the best constructive option for the 21st century.

Examples include the library of generic BIM objects of precast concrete products developed in ANDECE with one of the main BIM platforms on the market, Bimetica, recently extended and which aims to be the basis for precast companies to develop their own product catalogs; the publication of a particularized BIM guide for precast concrete, including a proposed strategy to be followed by companies, taking into account that can be very different if we refer, for instance, to a company specialized on pavements with a very defined portfolio or it is a company that supplies structure and facade and that has a greater rate of participation in construction projects; the organization of technical webinars such as the technological cycle carried out last spring to bring our companies closer to the main companies that are leading this digital transformation; or the subject of BIM and precast which is one of the most important that are part of the Master of Industrialized Construction in Concrete, the first specific training about precast concrete provided in the Spanish language at a global level.