Balanced-lift method for prestressed concrete bridges – 25 % lower cost compared to steel-concrete composite bridges

The first-time application of the balanced-lift method for the bridges

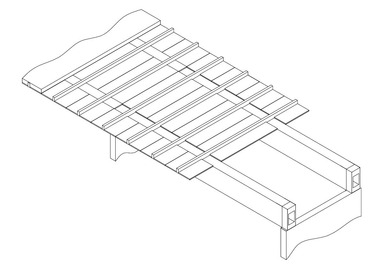

over the Lahnbach and Lafnitz rivers in Austria proved that these prestressed concrete bridges with 2.0 m high bridge girders

constructed according to this method incurred 25 % lower costs compared to the originally planned steel-concrete composite bridges with 4.2 m high steel girders. Costs could be reduced not only as a result of applying the balanced-lift method, but also by installing thin-walled, trough-shaped precast girders composed

of 70 mm thick precast slabs for the side walls and 120 mm thick bottom slabs. Tendons were incorporated in order to compress

the 20 mm thick joints between the precast slabs in the final

condition. Two 36 m long bridge girders were assembled in a vertical position for each of the bridge girders. Compression

struts were required for rotating the bridge girders from their initial vertical position into their final horizontal position. In the installed condition, these struts are part of the bridge structure and reduce its spans. After filling the compression struts and the thin-walled precast girders with in-situ concrete and completing the deck slab, the two bridges exhibit the same performance characteristics as conventional prestressed concrete bridges, providing the added benefit of a dense and visually appealing fair-faced concrete surface.

The balanced-lift method is also suitable for erecting replacement structures because it provides the option of installing the compression

struts and the bridge girders in the vertical position in confined environments. The use of precast elements for the compression struts and the bridge girders comes with the advantage of a short time to project completion because no formwork or shoring system is needed on the construction site.