Bauma 2016: Crusher for precast concrete plants and ME system

At the Bauma 2016 trade fair in Munich, Elematic headquartered in Finland once again presented itself as innovative supplier of plant technology for the production of precast concrete elements. On the stand, two highlights were exclusively presented to the BFT editors by the marketing manager, Nina Lehtonen, together with the responsible development engineer: The Atrex crushing mixer for the production of fine-grained aggregates at the concrete factory directly and the FloorMES E9 software for planning and supervising of a perfectly running precast hollow-core slab production.

The Atrex crushing mixer can be integrated into the Elematic production line for precast non-load-bearing partition walls of the brand Acotec. For the production of the Acotec wall panels, among others, expanded clay is used, however, the individual beads of the same are too large for the cement mix. The Atrex crushing mixer processes lightweight aggregates, thus it is able to crush even expanded clay particles to the size required. If a panel producer has integrated the crushing mixer in the production line, this means that he does not have to buy or store specific grades any longer. According to Elematic, the mixer allows for significant savings and simplifies the production process, especially in markets such as Russia and China, where such fine-grained aggregates are hardly available.

Production capacity of up to 120 m²/h

Last year, the Acotec production line was expanded by three new automation and capacity levels (see BFT International 10/2015, p. 52 ff.). This levels enable the Acotec production lines to meet the requirements of different countries in an even better way.

The Semi line with a production capacity of 80 m²/h is a simple line with efficient combined restacker handler and automated key functions. The Pro line provides a production capacity in the medium range of 100 m²/h and automated functions for all main processes, and the Edge line offers a top-class production capacity of 120 m²/h, only requiring two operators.

Optimized hollow-core slab production

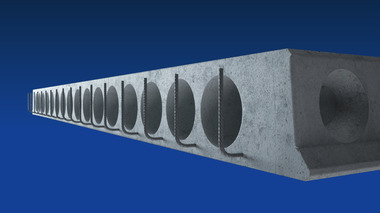

The second highlight shown at the Bauma stand of Elematic: For the first time, the Finnish company has launched a software for optimized planning and supervising of precast hollow-core slab production at a factory, by the introduction of FloorMes E9. The easy-to-understand graphic user interface allows planning and monitoring of the production from a central point of access in the factory by means of a display. The automated nesting enables precise positioning of hollow-core slabs to be respectively produced on the production line requested – including all block-outs. The system balances fluctuations in production due to the production of elements with varying levels of difficulty. Strand waste is reduced.

The automated planning of key functions and the possibility to make manual adjustments, if needed, simplify production planning and save time. Comprehensive current information on the status of production is available at any time. And as the production history is automatically stored, it can easily be used for further process improvement.

At present, FloorMes E9 is yet in piloting phase and will be officially available from September 2016 onwards.