New automated wall production at bauma

Longstanding bauma attendee Elematic is coming back to Munich with a host of technical innovations at this year’s show. The star of the 270m2 stand – Hall B, stand 323 – will be an all-new shuttering robot that is designed for solid wall, double wall and filigran concrete element production. The robot is the latest part in Elematic’s whole precast concrete plant automation technology offering. The company, already a leader in hollow core floors and sandwich construction walls, is now expanding its wall offering to include state-of-the-art double wall elements. When coupled with the company’s robot control system and whole-factory Plant Control system Elematic can deliver optimized automation that delivers the best precast factory layouts and processes for specific customer needs.

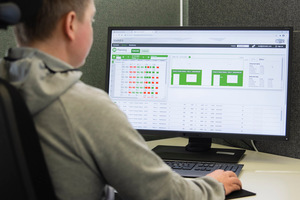

At the heart of this modernization is Plant Control, a suite of software that combines precast process optimization with the latest IT. A central element of the shift to automation, and paperless production processes, Plant Control streamlines operations, workflows and minimizes errors.

At the (hollow) core of precast floors

Traditionally, in hollow core slab production the concrete removed by creating the openings for HVAC and plumbing etc. goes to waste – wasted material, wasted cost and wasted transport. But thanks to Elematic’s Modifier E9 this is no longer the case. Working hand-in-hand with the Extruder E9 that casts the hollow core floor slab (and at up to 2.7m per minute is the fastest extruder in the world) – the Modifier E9 is a computer-controlled unit for creating openings during the casting process.

Significantly reducing the need for personnel, the Modifier E9 can automatically dig, plot and drill holes in double quick time, with the removed concrete automatically recycled into the Extruder E9 – with zero waste. Not only can this reduce the CO2 emissions of an average factory by an impressive 1000 tons annually, it can also offer that same average factory savings of €135,000 a year.

New saw family

Bauma will also see a new family of sophisticated floor slab saws unveiled. The multi-purpose Sawpreparer S5 not only cleans the slab before cutting – it can also pull the pre-stressing strands (each one of which can weigh 100kg) along the slab, reducing the need for manual pulling. Now with a simpler mechanism and reduced height to fit in lower production halls, the easy maintenance Sawpreparer can also cut slabs 100mm deeper, at 500mm, and at multiple angles. The blade is also now shielded by a telescopic cover – which lowers noise and blocks the progress of flying pieces from cutting.

Another new saw is the semi-automatic P7. Like the Sawpreparer, the P7 has a simpler and more reliable mechanism and a telescopic blade cover. It can cut up to 500mm and has a new blade movement and drive mechanism for easier maintenance. It also has a reduced height and features an updated control system, with intuitive user interfaces and improved cutting control programs. The bigger brother (and fully automatic) E9 also cuts to a depth of 500mm and shares all of the same upgrades. Both the P7 and E9 saws are available with much improved dust suppression. The classification for the filter is HEPA 13, which means that the dust-filled air of the cutting process is effectively captured, filtered and returned to the factory environment in a very clean condition.

Cutting, drilling and forming openings all have the potential to create bottlenecks in the production flow of a precast plant. But drilling-on-the-go is a prospect of Elematic’s all-new Drillbeam E9. Not only can it lift the slabs from the bed onto transport wagons, its three in-built drills can simultaneously and accurately drill the numerous weep holes that are required in hollow core floors. It can drill from below, at the ends and – unusually – in the middle of the slab.

Automatic for the people

Elematic is also launching a fully automatic slab transportation system – the Wagon E9-. Its zero-emission battery drive makes pulling cables unnecessary and all that is needed is to load the slab onto a wagon at each end and they will take the slab off to storage – with no need for human intervention. The Wagon E9 is guided by radars that ensure safety, and the trucks can be easily integrated into both new and existing factories.

Optimized automation, plant layouts and production processes combined with comprehensive plant digitalization solutions and technical and after sales support – Elematic has it all at this year’s bauma.