Berding Beton stormwater management system prevents flooding

This major project will take some more years to completion: Right in the city center of Oldenburg in Northern Germany, EWE, the regional utility group, plans to develop a completely new urban neighborhood including premises for retail outlets, service providers, housing and restaurants. The site awaiting development is situated between the Oldenburg Main Station and the Pferdemarkt, immediately adjacent to several existing EWE properties, covering an area of 4.5 hectares.

The project got the green light in early 2020 when the installation of the on-site infrastructure began under the contract awarded by EWE, including all roads, utility lines and sewer systems. Wessels und Grünefeld Ingenieurberatung, an engineering practice based in Garrel, and the Oldenburgisch-Ostfriesische Wasserverband jointly worked on the project design and engineering whereas the two civil contractors Otto Lieke GmbH & Co. KG and Meybau GmbH & Co. KG formed a consortium for executing the project.

5.7 million euro contract

One of the crucial components of the infrastructural design was to incorporate an effective stormwater management system. Previously, torrential rainfall events had proved the importance of taking the necessary precautions in order to prevent unwanted flooding and the damage resulting from it. The inner-city project site includes a high ratio of paved areas, which can cause major problems when it comes to the quick absorption and drainage of suddenly accumulating large amounts of water. This is why the project included not only precautions to ensure effective stormwater drainage but also a comprehensive range of preventive measures, such as sufficiently large detention basins for intermediate stormwater storage in order to prevent overloading of the sewer networks in the event of heavy rainfall. The project investment amounted to €5.7 million.

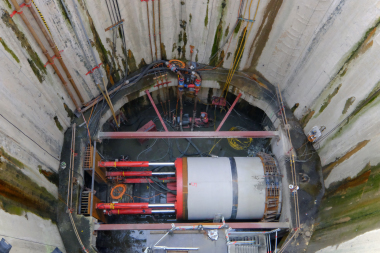

A sophisticated stormwater management system was conceived for the EWE site, complete with sufficiently dimensioned stormwater storage channels. Berding Beton was commissioned with delivering the full range of precast elements required for stormwater drainage. The company has many years of experience in manufacturing premium precast products for sewer systems. Its core expertise includes the production of elements tailored to customer needs. In this project, too, all box culverts, channels and manholes were custom-manufactured at the precast plant, which significantly accelerated the subsequent installation process. The contract included a total of 4,000 tons of box units as well as 1,000 tons of pipes and manholes. More specifically, the contractors installed 760 m of concrete pipe (DN 300/DN 1000) and 520 m of reinforced-concrete box culverts with the corresponding start and end sections. Some of these box units impress with their dimensions, such as a 250 m section composed of elements measuring 1,950 × 900 × 2,800 mm and weighing 12.5 tons each, or 110 m of 4,100 × 900 × 2,800 mm boxes, each with a weight of 22.5 tons.

Civil works completed on schedule

Berding Beton produced all precast units for the 17 installed stormwater channels to the highest quality standard. These watertight, buoyancy-resistant elements provide a high structural capacity as well as a high degree of flexibility. In addition, factory-installed seals create watertight joints between the box culverts. This impervious design relies on a glued-on, wedge-shaped sliding seal conforming to the EN 681-1 standard and a shear transfer element in different Shore hardnesses. This joint is watertight under both internal and external pressure of up to 1.00 bar.

Since water is a valuable asset, it should be handled in an environmentally friendly yet commercially viable manner. This is why the start and end sections of the stormwater channels were equipped with silt traps. A 31.4 ton flow-restricting structure comprising two DN 200 gates and a steel restrictor was installed in order to ensure controlled release of the stormwater from the detention reservoir. Berding Beton also delivered two custom emergency overflow systems measuring 2,000 × 2,000 × 2,100 mm and 2,000 × 2,000 × 2,200 mm, respectively. In this project, the civil contractors greatly benefited from Berding Beton delivering all items on schedule, thus saving valuable space on the job site, but also from the fact that the elements were installation-ready when arriving on-site.

In addition, the members of the Berding Beton staff ensured swift problem solving if and when required. As a result, all challenges were overcome in a joint effort, which allowed for timely completion of the civil works at the end of 2020.