CUBE BOX – First prefabricated carbon-reinforced concrete building – Design, production and precast element assembly

Carbon-reinforced concrete is a composite material that has been studied extensively since 2014 within the landmark “C³ – Carbon Concrete Composite” research project [1] funded by the Federal Ministry of Education and Research. In the final project phase, a building with a gross floor area of 220 m² will be constructed on the campus of TU Dresden using exclusively non-metallic (predominantly carbon) reinforcement. This landmark experimental building comprises a self-contained (semi)precast complex appearing in black on its outside (called Box), two twisted roof/wall portions (the Twist elements), and enclosing façades composed of steel and glass.

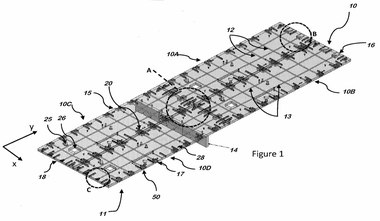

The two-story Box has been designed as a solitary building within the building; it has a footprint of about 4.9 by 10.7 m² and a height of 6.8 m. It consists of 23 semi-precast external and two internal wall units, nine floor slabs, and two stairs. The walls are based on the SysPro thermal wall design including two precast shells, an insulation layer, and a cast-in-place concrete core. Each of the shells is just 4 cm thick and fitted with a carbon textile layer. The intermediate space is filled with a high-performance insulation layer of just 7 cm thickness, and carbon-reinforced infill concrete is added on-site. The floor slabs are restrained uniaxially over a length of about 4.7 m. They have a hollow cross-section 3 cm thick flanges and 6 cm wide webs. Again, various types of carbon mesh and bar reinforcement are used in these elements [2].

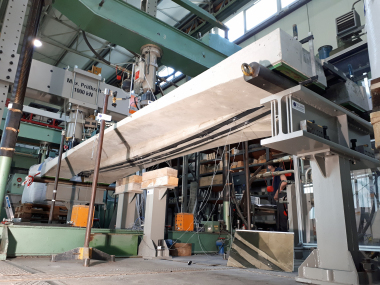

Design, production, and assembly of the precast elements were trialed as part of a technology test in summer 2019. The Box mock-up (a structure involving five walls and one floor slab) was erected successfully thanks to the close collaboration of all project partners (AIB GmbH, Bautzen; Assmann Beraten + Planen AG, Dresden; Leipzig University of Applied Sciences; Bendl Hoch- und Tiefbau GmbH & Co. KG, Sebnitz and Betonwerk Oschatz).