A reversible, circular timber-concrete composite floor system

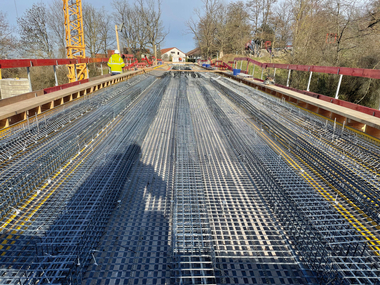

Timber-concrete composite floors can lower greenhouse gas emissions by reducing the concrete volume. In the composite section, the reinforced concrete slab primarily transfers normal compressive forces, while the timber component primarily transfers tensile forces. Mechanical or form-fitting fasteners create a semi-rigid connection so that the composite joint is designed to be as shear-resistant as possible for cost effectiveness. This makes it difficult to separate the sections for recycling into material-specific cycles, or for repurposing or reuse, at the end of the life cycle.

Against this backdrop, the collaborative research project “Circular (Recycled) Timber-Concrete Composite Floor System” jointly conducted by the Institute of Concrete Structures and Structural Design and the Institute of Steel Structures at the University of Kaiserslautern-Landau (RPTU) aims to design a shear joint that allows for the dry, reversible, and repeatable connection of reinforced concrete slab and glued laminated timber beam sections. A sawtooth-shaped notch geometry appears to be suitable for this purpose. To reduce or eliminate the need for additional screws, lifting forces and deformations are investigated both in numerical simulations and experimental tests in addition to the load-bearing and deformation behavior of the new composite joint.

CNC milling of formwork for concrete/timber prototypes that can be dry-jointed was successfully tested on a small scale. In push-out tests, the shear joint achieved a shear stiffness and resistance suitable for practical use at a notch depth of 2 cm and a flank notch/length of 25 cm. Applying concrete compressive strength classes according to CEN TS 19103 and a continuous shear joint design, shearing of the timber section was identified as the predominant failure mechanism.

This research is funded by the Federal Institute for Research on Building, Urban Affairs and Spatial Development on behalf of the Federal Ministry of Housing, Urban Development and Construction with funds from the “Zukunft Bau” program.