Choosing software for planning in the precast concrete plant

Also in the precast concrete industry, CAD planning is a subject for new discussions time and again. So Beton Fertigteil-Union GmbH & Co. KG was considering how to approach this task in a new way.

Also in the precast concrete industry, CAD planning is a subject for new discussions time and again. So Beton Fertigteil-Union GmbH & Co. KG was as well considering how to approach this task from the point of view of the management, the factory and the users in a new way. This strategic approach provides the advantage that they do not get bogged down in the infinitely diverse functionality of the programs offered by the providers.

Three criteria are important for the right choice: The crucial point is the philosophy of the programm, i. e. the answer to the question “what is the essence?” An additional aspect is the demand on the user when dealing with the product affecting the costs significantly. The software provider as such is a third remarkable viewpoint in terms of continuity, innovative strength and security of investment.

Product philosophy

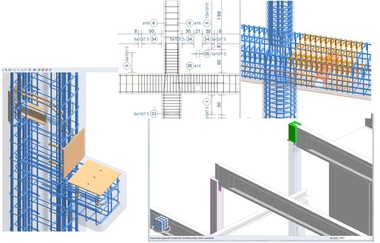

The following methods are common three-dimensional operating principles: The parameterization seems to be the impressive fact of the parameter method offering great advantages for cataloged building components. With the respective effort, it is possible to store the components, such as embedded parts or support solutions, in libraries enabling the user to create his model quickly. However, there is a disadvantage when it comes to layout editing. The automatism provides anything but a ready-to-build plan, but only the geometry that has to be prepared to a layout with much effort. In case of modifications of the model, the user has to start right from the beginning. Current practice is a construction-accompanying planning. This means that reactions have to be as flexible as possible and free from errors. In addition to this, an „easy-to-modify“ program is required.

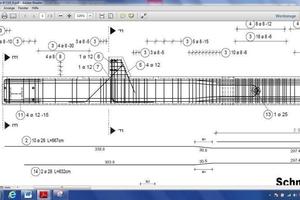

As an alternative, the user can create his three-dimensional model using the hybrid method, which also allows an automatic generation of plans. The functionality of the program enables, moreover, to derive ready-to-build plans. The automatically derived plan has to be reworked for complex precast components; in this case, however, the entire range of 2D functionality is available and the geometry corresponds with the 3D model.

Good and informative plans

Good plans will yet be required in the next ten to twenty years.The products will be more and more complex and the plans will be better and more comprehensible. The own staff members, testing engineers, partners involved in the planning process, and authorities still call for plans and eventually they are needed for documentation purposes concerning warranty and liability.

Provider‘s vision

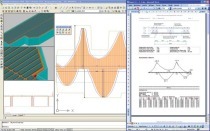

Today, everyone is talking about the term BIM (Building Information Modeling), like they used to do about CAD. In the meantime, it is however known that not every CAD system is suitable for a precast concrete plant. The aim is to gather data and information just once, that is where they come up. Therefore, there is the request for a holistic system which enables to direct such data and information through the processes for all those involved. The today still usual multiple input of data is an expensive source of error.

User and operation of

the program

The product portfolio of Beton Fertigteil-Union GmbH & Co. KG, ranging from precast floor slabs to complex architectural elements, is so varied that semi-skilled workers are unable to cope with the same. Even the planning of precast floor slabs requires draftsmen because the quality of the planning documents will likely be poor. It is necessary to have a program that can be operated by architectural technicians who are able to work in the project after a short start-up time.

Partner or seller of a license

The precast concrete industry is not only a market niche for software providers but also a sector with the highest demands on the software in the construction industry. Considering this backdrop, it soon becomes obvious whether a company is able to hold its ground in the market and has the innovative strength to progress even more. Beton Fertigteil-Union GmbH & Co. KG is aiming at a long-term cooperation with a software company. Therefore, the relevant factors are a company‘s financial as well as technical independence and a high market potential at the same time. The competence of a company in respect of the construction industry and precast elements is even more important.

Our experience

Beton Fertigteil-Union GmbH does no longer use mere 2D planning because BFT wants to benefit from 3D. The decision was therefore made in favor of a hybrid model since all three criteria mentioned above advocate this method.

A new employee with much skill in CAD planning was able to work on the project using this system within one week through „learning by doing“. Prior to this, he had to gain experience with a lot of effort and varying success on a parameterized system for more than half a year in order to be the just one of five employees being nearly as successful.

Cost factor planning office

From the management expert‘s point of view the internal planning office of a factory is a cost factor as the services could also be rendered by external service providers.

The following arguments are clearly in favor of an internal office: Flexibility, better prospects in tendering, early quantities for the stock planning, no new data input for operations scheduling, visualization of the project for all staff members, paperless office and thinking in terms of the whole project.

Summary

It is difficult to choose a new CAD system. Beton Fertigteil-Union GmbH & Co. KG analyzed the subject primarily with a strategic approach with the result to be quicker in precast element planning as well as in production planning than before while increasing the quality. The error risk tends towards zero without too much pressure on the employees.