3D measurement systems: from the measuring point to the BIM model

Complex geometries? Curved angles? Inclined walls and floors? Laser-assisted 3D measurement systems even capture sophisticated objects precisely and in compliance with BIM, too, as required.

Even though it is relatively easy to measure rectangular rooms or buildings with the aid of a tape measure, folding yardstick or laser distance meter, these devices completely reach their limits when it comes to complex objects, curved and inclined or free-form rooms. Specific, laser-assisted 3D measuring systems are much better suited in such cases. They capture 3D measuring point coordinates of any object using the horizontal and vertical angle as well as the measured distance. Afterwards, the digital measuring data can be transferred to mobile or desktop computers for evaluation. 3D measurement systems are not only used for as-built measurements, but also more and more in the planning stage for monitoring the target state and current state on the construction site, checking dimensions and execution quality, and to detect defects, respectively, or to document the construction works as part of the as-built documentation, for example. In this process, measured actual data of a building shell are compared with the target data of the plan or the BIM model, for instance.

Measuring point or point cloud?

Two fundamentally different measuring methods have established themselves for laser-assisted 3D measurement, these are: tachymetry and 3D laser scanning.

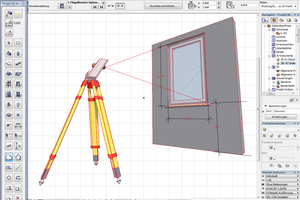

The tachymetric 3D measurement uses a laser scanner to capture 3D coordinates of distinctive points of the object individually – either by manually rotating and tilting of the scanner or motor driven by radio remote control. Afterwards, the 3D geometry data are transferred through data cables, USB stick or wireless using Bluetooth or WLAN technology to the measurement program that is usually part of the system. Right on site, if required, 3D measurement drawings can be created from the measured data using the associated software; these drawings can be transferred to the CAD program via interfaces. The tachymetry is particually suitable for swift, three-dimensional measurement of oblique-angled, circular or free-form rooms. There are also tachymetry solutions available which capture walls, columns or floors as BIM building components directly during measurement. They are used to create a three-dimensional BIM model, consisting of smart components provided with all attributes required for subsequent planning, that can be used for deriving floor plans, elevations, sections, volumes/quantities or cost estimates (e.g., using Flexijet 4Architects).

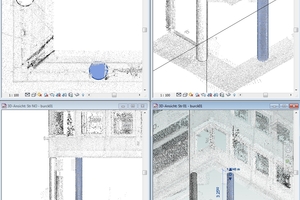

The 3D laser scanning is primarily suited for the capturing of complex, strongly structured objects such as wooden or steel structures or building services installations. In this process, a laser scanner, either tripod mounted or hand held, scans the environment from several locations in the room in the form of a dense grid of measured points, generating a 360-degree panoramic image simultaneously. This also enables capturing objects with very complex geometries including all details within a few minutes – both photographically and geometrically. Advantage of the technique and its disadvantage at the same time: Not individual points with importance for the measurement are scanned selectively, but millions of measuring points at random. This reduces the risk of omitting important measurements and hence the need for a second measurement on site. However, processing of the „point clouds“ generated is not possible on site directly, they must rather be evaluated in the office subsequently. For this purpose, the measured data are imported and filtered in a specific evaluation program or in a CAD program fitted with an appropriate interface. Horizontal or vertical sections or sectional views can be generated immediately by simply putting a sectional plane through the point cloud. If, on the other hand, the measured points shall be converted into CAD vector data, they need to be evaluated manually, or semi-automatically to some extent, and replaced by CAD elements (lines, curves, cuboids, cylinders, etc.) or BIM building components.

Combined systems and photogrammetry systems

In many cases, tachymetry and 3D laser scanning are used in parallel, because the methods complement each other. Room geometries, for example, are captured by tachymetry and details by laser scanning, then accurately overlapping the measurement data. Photogrammetric methods can also complement the 3D measurement. The HottScan measruing system, for example, combines the measuring systems of tachymetry and laser scanning with photogrammetry. A 3D measurement system, especially developed for this purpose, automatically scans the environment like a laser scanner in a grid-like manner, although at a considerably lower speed and a lower density of points. According to the measurement principle of tachymetry, about 30 measuring points are captured within a minute for the measurement of a room. Additional measuring points can be captured manually or by remote control, if required. In addition, a high-resolution, spatial 3D panoramic image is created by the individual images taken in parallel; this image can serve to clarify details on site at any time or to document the current structural situation, structural damages, or installations of building services.

After the transmission of measured data and photo files, the user can model three-dimensional rooms on the computer using the associated photo measurement software. For this purpose, the measured points are used to define spatial planes, into which CAD objects can be entered with millimeter precision. This gradually results in CAD measurement drawings, which can be transferred together with quantity evaluations by an interface to CAD programs and invoice or quotation software programs, respectively. Mere photogrammetry systems such as Philidas or PhotoModeler software, which are mentioned for the sake of completeness, are based on pairs of photo images taken by calibrated cameras or standard digital cameras. The images are interpreted according to the principles of stereo photogrammetry. For this purpose, the user clicks with the mouse on distinctive object points one after another in each image pair. Using these entries and with the aid of mathematic calculation methods, the software is able to position CAD objects in the room accurate to the millimeter and to generate three-dimensional CAD measurement drawings from two-dimensional photos.

What to consider when selecting a system?

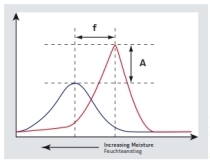

The measuring range and the accuracy are some of the most important technical parameters of 3D measurement systems: The first figure indicates the minimum distance up to the maximum distance the device is able to measure (e.g., between 0.3 and 50 meters). The measuring accuracy indicates, how precise an object point can be captured from its position at different measuring distances (e.g., between ± 1 and 4 millimeters). The angular accuracy of the two rotational axes also plays an important role here, it can differ enormously – depending on the system. The field of view provides the horizontal and vertical range in degrees, within which the measurement sensor can capture the measuring points. The horizontal line is always at 360 degrees and the vertical line is at about 300 degrees. This „measuring shadow“ of about 60 degrees occurring in case of free-standing devices, due to the design and the tripod, can be obstructive when measuring in cramped conditions, for example. It is therefore advantageous, if the system can also carry out vertical measurements almost consistently or if it is supplemented by a hand-held measuring device. For an efficient capturing of measuring points using tachymetric systems, it is decisive that the measuring points can be sighted optionally by motor-driven remote control, but also manually. Measuring points can be sighted much more precisely by motor, but manually it is faster. The actual measurement should also be triggered manually or by remote control as an option.

The maximum measurement rate indicates how many measuring points are captured per minute. Other important features are automated leveling when setting up the device or a shock sensor recognizing if the device is bumped accidentally, which is helpful, for example, at busy construction sites. Measurement series allow the semi-automated capturing of measuring points along a specified line or within a surface area. Tachymetric systems also allow for the projection of CAD data: So, CAD data (e.g., polygonal sections or drilling points, etc.) can be projected to a wall, floor or ground surface, thus eliminating time-consuming measuring. The data transmission of the measured data from the measurement device to the mobile computer should be carried out in a wireless way and simultaneously. Hence, the current measurement result can be checked continuously. It should be possible to export the measured data through a common export file format (DXF, DWG, IFC, etc.), enabling further processing in CAD software programs. The specifications of the casing, such as dimensions and weight, give information about the mobility, the degree of protection (IP code) as well as the material of the casing, and about the suitability of the device on construction sites (overview of the degree of protection: https://en.wikipedia.org/wiki/IP_Code).

Conclusion: It‘s the payoff that counts

Those, who want to measure in three dimensions on the construction site, must spend a little more money than on yardstick, measuring tape, pencil and paper. The costs range from 1,500 for simple systems and relatively few measuring points per measurement and about 14,000 euros for fully equipped tachymetry systems as well as from 15,000 to 60,000 euros and even more for 3D laser scanners with varying measuring accuracy and measuring ranges. This is added by annual calibration costs and maintenance costs (between 1,000 and 4,000 euros). No matter which system is used: 3D measurements are not available at the push of a button. Tachymetric measurement systems require to sight every measuring point individually, which can be quite challenging in case of large and complex objects with plenty of measuring points. The more complex the geometry, the more detailed the object – such as building services installations – the more elaborate is the capturing of individual points and the better the 3D laser scanning is suited. Those, who need measurements only from time to time, however, should very carefully consider beforehand, whether the investment costs and running costs will pay off at all or whether a service provider makes more sense because purchasing only makes sense if the device is used several time a month. A provider of scanning services is the better choice for a lower utilization. In this case, attention should be paid to the fact that the provider is not only able to operate the device, but also has the know-how and the tools to provide what the customers request. This may be 2D measurement images, finished floor plans, elevations and sections or a 3D CAD or BIM model. This partially requires engineering knowledge.

Supplier

Tachymetric systems:

//www.flexijet.info" target="_blank" >www.flexijet.info:www.flexijet.info, //www.hottscan.de" target="_blank" >www.hottscan.de:www.hottscan.de, www.leica-geosystems.de, //www.sekon.de" target="_blank" >www.sekon.de:www.sekon.de, //www.sl-laser.com" target="_blank" >www.sl-laser.com:www.sl-laser.com,

//www.prodim.eu" target="_blank" >www.prodim.eu:www.prodim.eu, //www.theocad.de" target="_blank" >www.theocad.de:www.theocad.de, www.trimble.com, //www.viz-all.fr" target="_blank" >www.viz-all.fr:www.viz-all.fr

3D laser scanner:

//www.deltasphere.com" target="_blank" >www.deltasphere.com:www.deltasphere.com, //www.faro.com" target="_blank" >www.faro.com:www.faro.com,

//www.geo-konzept.de" target="_blank" >www.geo-konzept.de:www.geo-konzept.de,//www.leica-geosystems.de" target="_blank" >www.leica-geosystems.de: www.leica-geosystems.de,

//www.maptek.com" target="_blank" >www.maptek.com:www.maptek.com, //www.riegl.co.at" target="_blank" >www.riegl.co.at:www.riegl.co.at,

//www.surphaser.com" target="_blank" >www.surphaser.com:www.surphaser.com, //www.topconpositioning.de" target="_blank" >www.topconpositioning.de:www.topconpositioning.de,

//www.trimble.com" target="_blank" >www.trimble.com:www.trimble.com, //www.zf-laser.com" target="_blank" >www.zf-laser.com:www.zf-laser.com

Service provider://www.1000hands.de" target="_blank" >www.1000hands.de:

www.1000hands.de, //www.3dcad-gmbh.de" target="_blank" >www.3dcad-gmbh.de:www.3dcad-gmbh.de,

//www.3d-laserscanning.com" target="_blank" >www.3d-laserscanning.com:www.3d-laserscanning.com, //www.bkr-laserscanning.de" target="_blank" >www.bkr-laserscanning.de:www.bkr-laserscanning.de, //www.christofori.de" target="_blank" >www.christofori.de:www.christofori.de, //www.farlo-projekt.de" target="_blank" >www.farlo-projekt.de:www.farlo-projekt.de,

//www.ing-wenck.de" target="_blank" >www.ing-wenck.de:www.ing-wenck.de, //www.inobatec.de" target="_blank" >www.inobatec.de:www.inobatec.de, //www.laserscanning3d.de" target="_blank" >www.laserscanning3d.de:www.laserscanning3d.de, //www.laser-scanning-architecture.com" target="_blank" >www.laser-scanning-architecture.com:www.laser-scanning-architecture.com,

//www.netzundplan.at" target="_blank" >www.netzundplan.at:www.netzundplan.at, //www.riemenschneider.net" target="_blank" >www.riemenschneider.net:www.riemenschneider.net,

//www.survey-service.de" target="_blank" >www.survey-service.de:www.survey-service.de,//www.unison-engineering.de" target="_blank" >www.unison-engineering.de: www.unison-engineering.de, //www.vbmassong.de" target="_blank" >www.vbmassong.de:www.vbmassong.de, (also see membership lists:

//www.vdv-online.de" target="_blank" >www.vdv-online.de:www.vdv-online.de und //www.bdvi.de" target="_blank" >www.bdvi.de:www.bdvi.de)

(This list of examples is not intended to be exhaustive)

for Publicly Appointed Surveyors)

German Surveyors)

und Tachymetrie bei einer Gebäudeaufnahme, Hochschule Neubrandenburg, Neubrandenburg, 2009,