Circular reinforced concrete bridge for Uruguay’s Atlantic coast

The bridge over the Garzón lagoon was proposed with the intention to unite the departments of Maldonado and Rocha, located on Uruguay’s Atlantic coast. The precast superstructure was completed with on-site concreting the upper slab. The sections of the accesses and fork were fully implemented with post-tensioned concrete.

The bridge over the Garzón lagoon was proposed more than two decades ago with the intention to unite the departments of Maldonado and Rocha, located on the south eastern part of the country’s Atlantic coast, but for a number of reasons the date of commencement of work was postponed several times.

Only in the month of September 2014, after financing and the environmental record was approved by the National Directorate of Environment, the Uruguayan company Saceem could begin construction of the bridge; whose short-term benefits are that it will replace the current system of crossing of people and vehicles on rafts. The new bridge will also increase the potential for tourism to the area. The completed bridge was inaugurated on December 22, 2015, just over a year after construction began.

Possible by a public-private partnership

The bridge design is quite unique as a whole, taking into account that any country would have normally opted for a straight bridge or perhaps a wide radius curve, however in this case the circular shape was chosen to minimize traffic speed and reduce environmental pollution and increase road safety at the same time. There is also a pedestrian walkway located on the outside of the bridge, which has become an attraction for local people, who can enjoy the lake from a perspective that was not possible before.

The completion of the work has been made possible by a public-private partnership between the Ministry of Transport and Public Works (MTOP) and Las Garzas Blancas SA, a company that contributed approximately 80 % of the value of the investment.

The work of post-tensioned beams was designed and executed with equipment and technicians from Saceem, a company that has an established track record in building bridges and traffic interchanges in Uruguay, having executed numerous works of this kind in addition to the most emblematic one being the “Bridge of the Americas” in Montevideo. They also built the bridge over the Rio Negro, the longest in the country with a span of 2,080 meters.

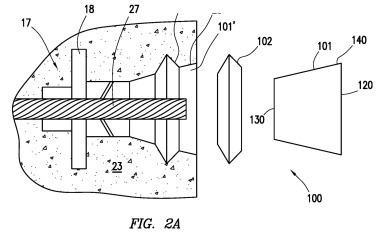

However, the architectural design of the bridge over the Laguna Garzón was born from the pen of the famous Uruguayan architect Rafael Viñoly, who proposed a single lane round bridge with entry and exit points diametrically opposed. The bridge consists of a circular central section with a radius of 51.5 meters (323 meters in length) and two straight sections at the entrances of 46 meters in length. The road is 5 meters wide and is bounded by two New Jersey-type protectors, out of which extend floating footpaths.

The geological survey of the land was carried out by numerous specialized professionals in situ tests, noting that the entire work area proved to be made up of quite uniform material despite being located in a lagoon. Technicians were able to determine that the stratigraphy within 15 meters deep water was made up of layers of sand particle of various sizes and with various levels of compaction. The lower layer was about one meter thick, and was composed of a mixture of sand and very compact clay, this layer was above a layer of decomposed rock and clay, and it was at this point the engineers decided to make the foundation bridge, which is located between 4 meters and 14 meters in depth depending on the location along the bridge.

Prefabricated sections of up to 70 tons

The earthworks were carried out basically by reclaiming land from the watercourse and for this reason a cofferdam was built accompanying plant bridge in a span of 18 meters to a height of 2.00 meters, which was guaranteed to work despite flooding. For logistical reasons the construction company executed the first half of the eastern part and then moved to the west side filling and completing the second half of the bridge. Thus half the runway was left open to the lagoon at all times. As provided for in the provisions of the environmental study, the edges and filling were protected from erosion using bags and geotextiles, while the implementation of soil movement was performed with two large-sized excavators, backhoe and a combined fleet of 10 trucks.

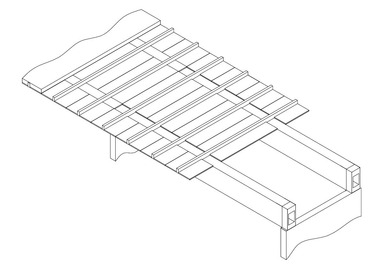

Foundations and pillars were executed simultaneously while the prefabricated sections of up to 70 tons each were built at the construction site to facilitate transport and also to meet the deadlines set for the project.

Once the pillars were completed, they were transported on the same prefabricated cofferdam using special buggies adapted for this purpose and they were mounted utilizing a large crane operated by the Salomon Company. The pillars were set side by side to form the main ring of the bridge. This process followed a strict schedule of well-organized work, first carrying out the work on the east side and after mounting the prefabricated sections the cofferdam was removed to move it to the west side and repeat the same process.

The superstructure was completed with on-site concreting the upper slab. The sections of the accesses and fork were fully implemented in situ with post-tensioned concrete.

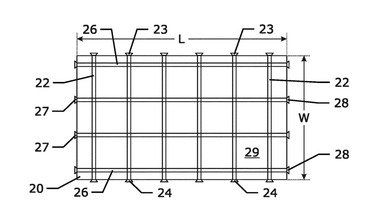

Superstructure of reinforced and post-tensioned concrete

Except for the two access ramps, the columns are the Pilar-Pilot type, ie without transition elements. The excavation of the piles, 28 in total, was performed using metal and bentonite given the high permeability and instability of the ground. The diameters range from 80 cm at the entrances, 140 cm at the roundabout, 170 cm and 220 cm in the fork. For the latter it was necessary to incorporate a large-sized piloter for the implementation of large-diameter bored piles. The different sections that make up the roundabout were manufactured on the construction site on perfectly level concrete esplanades. Once positioned the active and passive reinforcements molds were placed for the outside walls, designed and manufactured on site by Saceem.

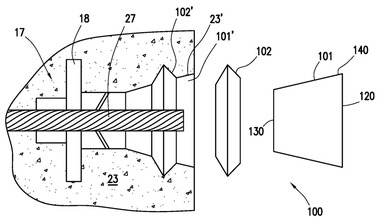

The final design consists of 6 finally founded on piles and pile caps 16 pillar-type piles 25 meters long. On it the superstructure of reinforced and post-tensioned concrete met with trapezoidal section hollow beams were executed, although two different types can be distinguished: At the roundabout single-cell box beams made up of self-supporting prefabricated troughs 20 meters of light that are complemented are the construction site with the upper slab. On the approaches to the bridge and fork to the roundabout, in this case the girder is multi-cell and completely executed on site. Finally, it ran on both sides of the road and across the length of the bridge New Jersey- type protection made of reinforced concrete.