Seeblickweg bridge – 70-meter long timber-carbon concrete composite bridge

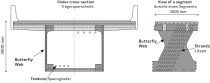

With this 70-metre-long structure, both an optimum load transfer for the specified length of the bridge and an optimum symbiosis of the materials (timber, concrete, carbon reinforcement) in terms of serviceability and durability in full harmony with sustainability were brought into balance. It features a two-span girder design and associated alternating bending stresses acting on its cross-section. This is why this was designed as a full-carbon

T-beam at the central bearing, and as a timber-concrete

composite in the span section. This approach permitted optimum

utilization of the positive characteristics of the two materials.

Glued-in shear plates connect the CNC-milled timber

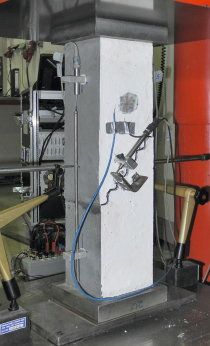

cross-section to the concrete slab. Shear forces are transferred from the timber beam into the concrete superstructure through axially loaded, glued-in GFRP bars having a “shear stud” in the concrete. At the abutments, the full concrete cross-section has a maximum thickness of 59 cm and is reinforced with eight layers of carbon mesh in the tensile zone. Carbon bars were used for the stirrup

reinforcement to transfer the shear forces. Using non-metallic

reinforcement eliminated the need for a protective layer, which is why the concrete mix design had to fulfill specific requirements. In addition to being resistant to freeze-thaw impact (XF4), the mix needed to be sufficiently flowable (F5) to allow for in-situ concrete pouring of the bridge. To give the construction contractor a better

understanding of how to handlecarbon-reinforced concrete, concreting tests were conducted in advance while considering the dense reinforcement design.

Engineering practice Harrer

was commissioned with the entire project planning and structural design in close coordination with the civil engineering department of the City of Stuttgart. Structural

verification was based on the guideline for designing concrete components with non-metallic reinforcement.

The combination of the two materials and their effective application make this construction method exceedingly efficient and climate-friendly.