Cost-effective use of fine and ultra-fine materials in standard and high-performance concretes

Concrete mixes include a wide range of different natural raw materials. The local conditions prevailing for natural raw material resources make any input material, and thus mix design and, in some cases, the mix itself, relatively unique. However, the structure and composition of concrete mixes is normally based on standardized framework parameters rather than on the specific raw material properties. This means that at least some of the potential offered by the specific raw materials is not utilized.

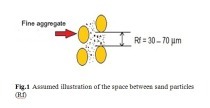

The Quantz technology developed by G.tecz is applied to specifically intervene in the composition of the mix by calculating the packing density and water film thickness of fine and ultra-fine constituents as well as aggregates, and subsequently adjusting these parameters to the target characteristics of the mix.

Analyzing the locally available raw materials used in the mix makes it possible to develop and implement a custom mix design providing specific properties. The Quantz technology can be applied to any type of concrete, including standard, high-performance and ultra-high-performance grades.

Selecting and using appropriate fine and ultra-fine materials has a direct influence on the properties of such concretes in their fresh and hardened states, including their rheological characteristics, strength development and, most importantly, durability.

In concrete mixes developed or adjusted with the aid of the Quantz technology, the cement content can be reduced and costs can be saved while retaining the same performance characteristics or even improving them.