Cracking behavior and splitting failure mode

in textile-reinforced concrete

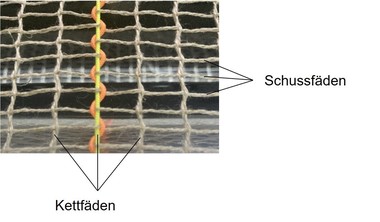

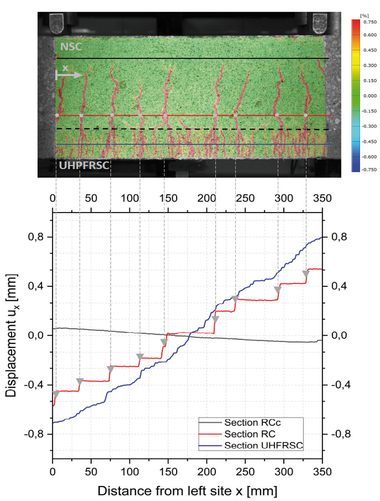

The existing knowledge of the bond behavior of reinforced concrete cannot be transferred “as is” to textile-reinforced structures. The bond between textile reinforcement and concrete is dependent on various parameters. As a result, the bond behavior and thus the occurring crack spacing and crack widths differ significantly depending on the type of textile reinforcement. A pronounced tendency to develop splitting cracks mainly orientated in the layer of the textile itself was additionally observed in some types of textile reinforcement.

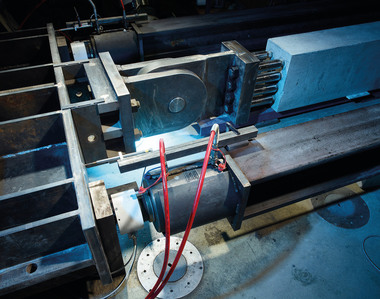

Numerous investigations were carried out in recent years at

TU Wien to identify key parameters influencing the bond behavior of textile reinforcement and their effects on the cracking behavior in such structures. In these studies, mainly fully impregnated fabrics with a high yarn count were investigated. The experiments included not only bond performance tests on single yarns but also uniaxial tensile tests of the composite material. Among the parameters varied was the geometry of the fiber strands as well as the concrete cover.

In the course of the studies, it was shown that if the investigated type of textile reinforcement exhibits a high transverse stiffness a mechanical interlock with the concrete can be achieved that leads to a high bond stiffness and strength. A prerequisite for this behavior is a regularly repeating variation of the cross-sectional dimensions exhibited by the fiber strand. Whether this, in turn, is accompanied by a higher tendency for longitudinal cracking mainly depends on the cross-sectional geometry of the strand. If it has a flat, elliptical shape, splitting cracks predominantly occur in the layer of the textile reinforcement. Due to the specific orientation of these cracks, no significant influence of the concrete cover on the initiation of a splitting crack could be observed, but a significant influence on the spalling of the concrete cover can be recognized.