Crack-bridging effect in strengthening of reinforcedconcrete structures using sprayed UHPFRC

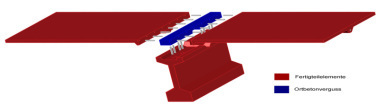

This presentation discusses the repair and strengthening of reinforced-concrete structures with Ultra-high Performance Fibre Reinforced Shotcrete (UHPFRSC), with special focus on the crack-bridging effect. UHPFRSC is characterized by outstanding mechanical properties as well as by high resistance against aggressive media. In the investigations performed, the ultra-high-performance material is applied as shotcrete.

Application of the material in the form of shotcrete, due to its specific processability, requires special requierments. However, processing is possible by means of conventional construction equipement. When subjected to tensioning, UHPFRSC exhibits a strain hardening behavior and, correspondingly, multiple cracking, thus ensuring high durability. The aim of the research is to increase the load-bearing capacity of impaired reinforced-concrete constructions and, at the same time, to extend their service life-time. The material behavior here enables effective crack distribution with small crack widths. Restriction of crack widths in the UHPFRSC layer is intended to impede pene-tration of chlorides.

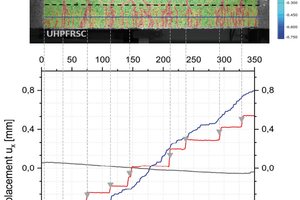

In four-point bending tests demonstrated the crack-bridging effect of RC-UHPFRSC composite element was shown. The illustration shows the multi-crack formation in the UHPFRSC-layer on RC elements. The additional UHPFRSC-layer is capable of reducing local penetration of chloride along existing macro-cracks in strengthened RC elements. The service life of repaired and strengthened reinforced-concrete structures therefore be extended. In addition, results demonstrated, by using ultra-high-performance concrete as additional layer, an increased load-bearing capacity of composite elements compared to reference elements. These investigations confirm the potential of UHPFRSC as suitable material for repairing and strengthening reinforced-concrete structures.