Delivery readiness up, inventories down – Efficient scheduling of precast concrete stock-keeping units

Supply chain disruptions and insufficient security of supply have been at the top of the list of causes of significant sales and revenue losses in the entire construction materials industry, especially in recent years – which also applies to the segment of stocked precast concrete elements. But how can we optimize the weak supply chain performance?

Supply chain disruptions and insufficient security of supply have been at the top of the list of causes of significant sales and revenue losses in the entire construction materials industry, especially in recent years – which also applies to the segment of stocked precast concrete elements. In a strongly seasonal market environment, it has not yet been possible to match the delivery performance of other sectors despite the overcapacities that continue to exist on the production side. The lack of transparency across the supply chains makes it difficult to identify inefficiencies and thus the potential for significantly increasing the business success of companies. But how can we create this transparency in order to optimize the weak supply chain performance?

Concrete products such as aerated concrete and paving blocks, structural precast elements such as walls, slabs and columns, as well as pipes and manholes, are delivered to wholesalers, DIY stores or directly to the construction sites of end users. Precast businesses usually produce them in campaigns for stocking purposes, thus decoupling them from individual customer orders and storing them in warehouses instead, aiming to achieve the highest possible production efficiency. The main constituents required for production – cement, sand and gravel – are basically available at any time as input materials because of the regionally focused sourcing pattern, which is generally less prone to disruptions compared to the highly fragile supply chains we are currently seeing in the economy as a whole. Basically, the “only” thing producers who manage precast element inventories need to do is to accurately forecast future demand trends in order to always keep the right items, also referred to as stock-keeping units (SKUs), in stock in the right quantities.

The goal: High delivery readiness

At first glance, production campaigns should be planned more comprehensively and warehouses filled to the greatest possible extent in order to effectively avoid situations in which regular seasonal demand cannot be met in a timely manner. The required level of delivery readiness should ideally be in the 95 to 98% range. However, the closer we get to the target of almost 100% readiness, the larger the volumes of finished products to be kept in stock will be. This is because demand is volatile in nature. To be able to satisfy peak demand levels whenever they occur, large product quantities inevitably occupy warehouse space also during off-peak periods. Yet, because a finished goods warehouse also has a high inherent value, ties up capital and incurs costs on an ongoing basis, another management objective is to limit stocked quantities to a reasonable level. The ongoing costs of warehousing in particular are often underestimated. Capital costs, costs of material handling and storage as well as warehouse management and insurance add up to 19 to 30% of the inventory value every year.

Thus, the question arises whether the assumptions used to plan campaign frequencies and volumes are based on an accurate forecast of sales volumes, and whether the associated demand patterns are optimized across the entire product range such that the manufacturer is in a position to maximize overall operating efficiency. Is the envisaged high delivery readiness actually achieved with the lowest possible finished product inventories and the best possible manufacturing efficiency? This is obviously not the case because it is a well-known industry phenomenon that delivery performance is sometimes extremely weak depending on seasonal effects.

The problem: Demand volatility

It is no easy feat to prepare sufficiently accurate sales forecasts that result in high delivery readiness and thus sales and earnings without overstraining warehousing capacities or compromising manufacturing productivity. On the one hand, needs are volatile on the demand side. On the other hand, customers expect to be served immediately since any delay on the job site will trigger various chain reactions in the construction process, which they want to avoid at all costs. However, it is not only major construction sites that require high delivery readiness despite volatile demand. Merchants also expect immediate deliveries because they are also part of the construction sites’ supply chain, and their ability to build the buffers necessary to meet upward and downward demand trends is limited. Some of the DIY stores impose even stricter requirements. After all, they forecast their revenues according to the turnover rate per square meter of retail area. They will miss out on revenues if the latter is not always sufficiently stocked. In addition, DIY stores often require just-in-time deliveries because of their limited warehousing capacity – they would run the risk of having to pay contractual penalties if they did not.

Thus, the demand side is already under a lot of pressure if the aim is to meet as many demands as possible in seasonal business while keeping inventories as low as possible with an optimally adjusted production output. In addition to production requirements, however, ordering requirements must also be taken into account for overall economic efficiency.

Challenges to ordering

In the case of cement – and lime if and when required –, for example, the flexibility of the suppliers’ production output is limited owing to the burning processes in the kilns. Any forward-looking synchronization of the respective demands will thus open up cost reduction opportunities in the precast producers’ sourcing processes. This is due to the fact that higher logistics costs should be expected when specific orders are scheduled at short notice. Currently, this is a particularly hot topic because volatile demand means that a growing share of products has to be sourced not from the nearest plant, but from more distant sites operated by the lime and cement producers. This factor is becoming increasingly important in view of exceedingly high fuel prices, which is why businesses in this sector pay increasing attention to it.

In addition, there are packaging materials, such as empty bags, as well as chemicals, pigments and input materials for finishing whose delivery lead times amount to several weeks (if not months or quarters as is currently the case) rather than days owing to the limited production capacities of a few key suppliers and the long procurement times on the global markets.

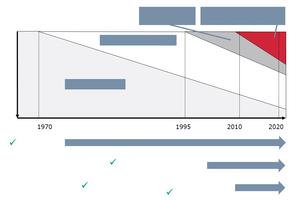

Strategic demand forecasts are essential

Despite their seasonal volatility and fluctuations related to large orders, sales forecasts and campaigns by DIY stores and merchants must thus reach far into the future while encompassing product ranges that can include several thousand different items for which numerous scheduling parameters should be set, which are to be handled differently depending on the specific item. Items that are ordered infrequently and in smaller quantities must be scheduled differently than products that are in constant and frequent demand, and new launches must be scheduled differently than discontinued products. Items supplied to many different merchants generally show more constant demand patterns and need to be scheduled differently than items that are sold primarily through major orders or items involving large promotional quantities.

Creating transparent rules for complex interdependencies

The factors referred to above as well as many others, such as minimum order quantities and minimum lot sizes for production, add up to an extremely complex set of rules that includes over 100 parameters. Such sets of rules must be created, optimized and maintained continuously to strike an optimal balance between the supply chain and the production output. However, there is a scarcity of human resources appropriately qualified for such challenging scheduling tasks, which are usually not part of the curriculum of a standard business administration degree or commercial training course.

The development of such rulesets thus requires experts who possess the necessary methodological expertise to analyze item master records and optimize parameters while also being able to facilitate optimization processes involving all stakeholders on the shop floor. After all, the aim is not just to increase the efficiency of individual departments but to maximize overall operational efficiency while ensuring the highest possible level of delivery readiness. After establishing the rules and optimizing the scheduling parameters, the medium-term goal should be to be able to schedule as large a proportion of item categories as possible in a highly automated process.

Automation of scheduling

If companies producing precast elements and concrete products want to implement such highly automated scheduling systems, they should know how to design such systems, which need to be highly sophisticated owing to the highly seasonal nature of the business and the limited production capacities required to meet rapidly rising seasonal demand at short notice. It is a big challenge to set these systems up so precisely that a large proportion of the items can be scheduled automatically or at least with a minimized workload for employees.

Accurate data is essential – also for artificial intelligence

However, the crux of the matter lies not only in implementing an optimized scheduling process on the basis of historical data and new influencing factors arising from the forecasts prepared by the sales department, from special requirements for large orders and from promotions for DIY stores. This is not an easy feat even if only considered on its own. In addition, it is crucial that the existing master records of all these items are maintained properly. For example, inventories that are built to increase production efficiency should not be mixed with safety stocks kept available to meet volatile demand patterns. Such factors should be manageable independently of each other – only then will it be possible to continue to apply the automated scheduling process amid changing conditions. It is thus essential to ensure an exceedingly accurate differentiation and maintenance of planning parameters in order to achieve the best possible results.

Reliable scheduling data is also a prerequisite for the effective use of tools such as artificial intelligence for forecasting the demand for safety stocks, for example, that provide the potential for additional efficiency gains compared to conventional methods.

The bottom line

Accordingly, key areas of activity lie in establishing and optimizing a continuous, accurately adjusted planning chain – from sales forecasting to scheduling – as well as in optimizing all data and parameters necessary for the planning and scheduling of items. Taken together, both areas provide the basis for automated management decisions, and thus for improved and more efficient supply chain processes. Forecasting and delivery readiness are enhanced significantly while safety stock levels are determined more reliably – especially in the case of infrequent orders and seasonal demand – based on distribution-free methods, and decision-making mechanisms are developed that trigger orders in a timely manner.

These are many different requirements, but how big is the benefit? Simulations and analyses based on artificial intelligence make the results of such efforts economically tangible. This means that the economic benefits of the digital transformation in the construction materials industry can now be expressed in figures, and made transparent.

The ultimate goal is to enable the entire construction materials industry supply chain to implement more accurate deliveries on the basis of lower inventories and optimally adjusted production outputs – irrespective of the quantities or type of product, point in time and delivery destination. Applying the right methods wisely makes it possible to achieve delivery readiness levels of 95 to 98% also in the construction materials industry.