Fantastic trade fair suffers from strike

“The strike once again disturbs everything,” commented the French businessman on the frantic crowds at Gare du Nord in Paris. At this transport hub, the man had to take the commuter train, just like the BFT editor and many others who wanted to visit the Intermat/World of Concrete Europe trade fair between April 23 and 28, 2018.

The complaints about the walkout of the workers of the French SNCF rail company protesting at the reform of the national company and the strike of the Air France airline staff, which took place simultaneously, for a pay rise were repeated later in exhibition hall 6, where the World of Concrete Europe special exhibition was held as part of the Intermat trade fair, by many representatives of the exhibiting companies; nevertheless they also expressed hope that the number of visitors might increase in the second half of the week.

According to the closing report of the trade fair organizer Comexposium, a total of 173,300 visitors from 160 countries came to the exhibition center in the north of the French capital city. Unfortunately, it seems, that this influx of visitors for the most part missed exhibition hall 6. This did not change in the second half of the week either, according to several exhibitors interviewed by BFT International subsequent to the fair.

Outstanding organization

This is very unfortunate since the organization of the Intermat was outstanding. About 1,400 exhibitors from all over the world presented their products and services in the five exhibition halls and in the open-air area, including more than 200 exhibitors from the concrete and precast concrete production sector, which were concentrated in exhibition hall 6 under the roof of the World of Concrete Europe special exhibition.

Moreover, the organizer presented the show under the motto “innovations”. This should be experienced and apparent everywhere, starting with the five exhibition sectors “earthmoving and demolition”, “minerals industry and foundations”, “building and concrete sector” and “lifting, handling and transportation” through to the lecture and workshop program. The theme villages “start-up”, “building smart” and “demolition and recycling” also attracted wide interest; here theme zones with small exhibition counters and space for presentations provided the companies with the opportunity to introduce themselves and to communicate with the visitors directly.

Client database and virtual reality

The stands of the “World of Concrete Europe” exhibitors had plenty to offer, too. Quadra, the French manufacturer of machines and equipment for the production of concrete products, presented, among others, two service innovations: A new database will be available for all customers of Quadra in the future. In a private and protected area of the database, they will be able to upload all documents associated with Quadra machines or equipment, thus documenting the condition of the same; this will include storage of text as well image documents. The database can be called up and maintained anywhere with a desktop computer or mobile devices; it will assist customers and the after-sales service of Quadra in operation, trouble-shouting, and maintenance.

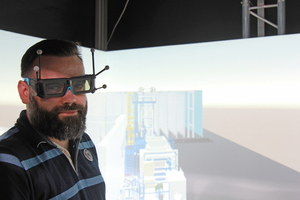

The second innovation could be tested by the visitors themselves at the stand directly: In a separated and shaded area covering about 2 m² a projector beamed the simulation of a Quadra circulation plant to the wall to be experienced by the visitors in 3D with the aid of a virtual reality gear. “We use the simulation already now for presentations. In this way, customers or potential customers get a convincing impression of how their plant could look like later,” stated Yannick Ancrenaz, the managing director and owner of Quadra, in a conversation with BFT International.

3D printing with concrete

An innovative presentation was also shown by the BSC (Béton Stone Consulting) company, which is representing, among others, the companies Kniele, Würschum, Incite AB, WMW Industrieanlagen, Eco Frog, Kobato, Manits ULV, Solidian, Via Domo and WKB Systems in France. All brands mentioned were represented at the large joint stand which was decorated under the motto of 3D printing with concrete.

“Our 3D printing process has many advantages,” stated Philippe Roux, the founder and owner of the French XtreeE start-up company, furnishing the BSC joint stand with exhibition objects. “Compared to conventional production processes it allows saving up to 70 % of material, which means a reduction of the CO2 footprint simultaneously. The process allows very fast and safe construction, offering comprehensive freedom of design along with the possibility to design structures efficiently.”

The technique and the associated plant technology, which the start-up has developed and composed in cooperation with Lafarge Holcim, ABB, Vinci Construction, and three other partners, allows manufacturers to produce load-bearing, structural precast concrete elements. Apart from the precast concrete elements made in a 3D process, mixers and plant equipment as well as further supplier products of the companies represented on the stand were exhibited, which partly can be used for the production of 3D precast elements.

Text: Christian Jahn, M. A.