Film coating boosts turnover in precast plants

Many precast plants are now successfully focusing on architectural concrete and are investing significant amounts of time and money into this engagement. Many customers, primarily architects, appreciate this commitment, the resulting knowhow, and the high quality of craftsmanship provided by these highly specialized companies. But concrete has succeeded in becoming the most important construction material not because of its appearance, but for its durability, strength, incombustibility, and cost-efficiency. Its appearance is rarely the reason for specifying concrete: in particular, for double walls and sandwich elements. The client accepts the more or less successful concrete surface and commissions plasterers, painters, tilers, or masons – and/or façade construction specialists – to adjust the optical properties to his wishes. For this reason, precast plants have until now lost out on this particular link in the added-value chain.

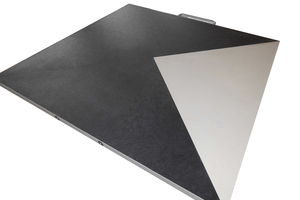

Special film coating in the concrete plant

An cost-efficient method to move business turnover into the precast plant is to coat the concrete surfaces with special film in the plant. An unlimited choice of designs is available – including those depicting unicolored surfaces, wood, natural stone, metal, and, it goes without saying, architectural concrete as well. The range of available film surfaces is virtually unlimited: glossy, matte, or slightly structured, to mention only a few. The surfaces are clearly defined in advance; i.e., the architect receives a sample identical to the film on the concrete element to be treated. The fire resistance of film-coated concrete elements is superior to that of HPL panels such as Thermopal, Trespa, or Resopal, and also to composite aluminum systems including Alucobond or Dibond. Laminating is a simple method that requires little investment and no specialist workers for precast plants to offer walls for façades, bathrooms, and floor slabs with a finished surface. Special films that are robust, age-resistant and easy to clean are commercially available and have been used in such projects as façade panels in branches of McDonald’s and KFC.

The printing costs for the films can be minimized when several plants share the same designs. The films are very stiff and can accordingly be used until now only on flat panels, and edges covered with film must be visibly rounded. Since ambient conditions vary worldwide in every climate zone, and since the demand for automation is different in every country, glues and application methods must be developed and adapted locally. This is the only solution for meeting all requirements involving weather resistance, fire protection, and cost efficiency. The price for the films, according to the author, is comparable to the price of cosmetic treatment, hydrophobizing, or graffiti protection.

Possible acceptance and risks

The question remains whether ultimate customers will accept the concrete surfaces coated with film, or will insist on the original concrete surface. Kitchen worktops and furniture, for example, are primarily manufactured from coated derived timber-material board, and many apparently natural-stone floors are in actual fact outstandingly imitated ceramic flooring. Film-coated precast elements will certainly not replace high-quality architectural-concrete applications with formliners and pigments. Film-coated precast concrete elements are likewise just as surely an outstanding possibility on a function-oriented mass market to enhance the sales of precast production plants. The German consulting companies Durcrete and Prilhofer have jointly begun to develop such systems with film-coated concrete elements up to marketability. The most recent alternative was presented at Engineering Days 2017 in Vienna and generated enormous interest, primarily among manufacturers of partly-precast components.