Flexible welding lines for precast concrete factories

Eurobend offers solutions for every precast plant lay outs that are suitable for any element dimensions and types of application. Its tried-and-tested PL XY and PL AMM mesh welding lines are designed to produce standard and customized mesh as well as mesh with openings for a wide range of precast elements. Eurobend machines are equipped with high-end features, sophisticated electronics, a software package and computer hardware with a redundant storage system for eliminating the possibility of production down times due to hard disk defects or data loss and an interface for exchanging of manufacturing data in various formats commonly used in the precast industry, such as BVBS or Unitechnik. They are easy to operate and to maintain thanks to their ingenious, modular design.

Both machine series provide an appropriate solution for any budget plan, as they are offered with either the pre-cut wire feeding option, on the entry level PL XY Series, or with the fully automatic wire feeding option from coils on the top-of-the-range, the PL AMM Series.

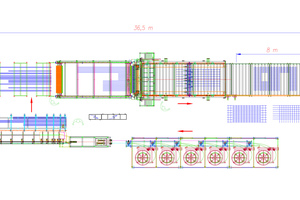

The production of standard mesh, customized mesh and mesh with openings is covered by the high-end CNC programmable mesh welding line PL XY Twin working from pre-cut bars.

Standard and custom reinforcement mesh with openings

It produces mesh with maximum diameter up to Ø20mm for both, line and cross wires. The PL XY is equipped with either one or two moving, multi-point welding blocks, achieving up to 400 welding points per minute. The produced mesh can have minimum line wire spacing of 50 mm and above, in 50 mm steps; the cross wire minimum step is 50mm and above infinitely programmable. Mesh with the above characteristics can be produced just-in-time on a type-by-type basis, without requiring any adjustments. The manufacturing process is controlled by the machine’s computer program.

Line wires are manually inserted into pre-selected grippers that are mounted on a carrier unit. The carrier unit then automatically feeds the line wires into the welding machine and returns to the start-up position for the next feed cycle while the machine is welding the mesh. Each gripper of the carrier is equipped with a LED-light, facilitating the line-wire feeding. This system minimizes the idle time between two meshes produced. A secondary feeding system on the line wire carrier enables the production of mesh with variable line wire lengths within the same or mesh with openings.

The cross wires are fed into the welding line automatically from a cross wire feeder. A secondary cross wire feeding and positioning system enables the production of mesh with variable cross wire lengths as well as mesh with openings. In the latter case, an additional display simplifies the feeding of cross wires in custom lengths. Finished mesh products are automatically removed via a mesh stacking unit and roller conveyor system.

Production of the pre-cut bars

Next to the mesh welding line, an independently operated multi rotor straightening and cutting machine MELC Flexiline machine is located that is equipped with Eurobend’s maintenance free 5G rotors with hyperbolic rollers is and land the extremely fast diameter changeover system (patents). This machine ensures perfect straightening quality and highly accurate lengths. It enables diameter changeovers within just three seconds without moving mechanical parts and produces precut rebar either on demand or according to a daily production schedule.

The extremely fast diameter changeover system provides the possibility to produce precut rebar one after another for each mesh in a batch. The pre-cut bars are delivered to a pocket chain conveyor.

Fully automatic production

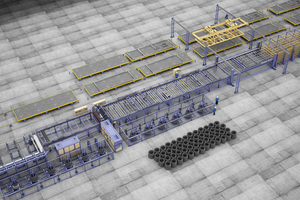

The high-end PL AMM mesh welding line produces mesh from coiled line and cross wires in diameters up to Ø20mm and up to Ø16mm respectively. It can be equipped with up to 81 stationary welding heads and achieves a working speed of up to 40 cross wires per minute. The smallest line wire step for all diameters is 50mm; above it is programmable in 50mm steps.

The minimum cross wire step is 50mm and above infinitely programmable. In the system there are two multi-rotor straightening and cutting machines of the MELC Flexiline series equipped with Eurobend maintenance-free 5G rotors with hyperbolic rollers and the patented wire guiding convergence system ensuring perfect straightening quality and length accuracies. They enable diameter changeovers for one and the same mesh within just a few seconds, thus making it possible to weld up to six different line and cross wire diameters in a single mesh.

Any mesh products can be fabricated one after another just-in-time on a type-by-type basis without any manual adjustments. The manufacturing process Everything is controlled by the machine’s computer program. A software interface enables the machine’s computer to exchanges production data with the factory’s environment in various industrial formats. Finished mesh products are automatically removed via a mesh stacking and roller conveyor system. They can also be bent with integrated bending units, can be stored in intermediate buffer systems or automatically placed on circulating pallets in a just-in-time process.