Flexstren – the winning solution for concrete pipes

Thanks to the Flexstren technology, concrete pipes have new functional characteristics that greatly expand the field of use, at extremely competitive costs versus GRP and plastic pipes. Easily applicable by any concrete pipe manufacturer, Flexstren will open up new markets such as irrigation, and the pressure part of the sewage applications (concrete pipe producers can now supply pipes for forcemains), along with thermal / hydroelectric plants.

Flexstren concrete pipes have the following specifications:

They no need to be reinforced with steel reinforcing cages, so they are corrosion free.

The external post tensioned composite wrapping ensures impermeability even for pressure applications (more than 3.5 Bar), and the Flexstren concrete pipes can also be buried on aggressive soil environments.

Flexstren Jacking pipes have a much greater axial capacity.

The elimination of a minimum depth of covers makes it possible to do pipes with a thickness 1/20 of the diameter. So thin concrete pipes have semi-rigid behavior, with easier soil compaction vs fiber / plastic pipes.

It becomes possible and cost effective to do concrete pipes with diameters down to 200 mm.

The production process

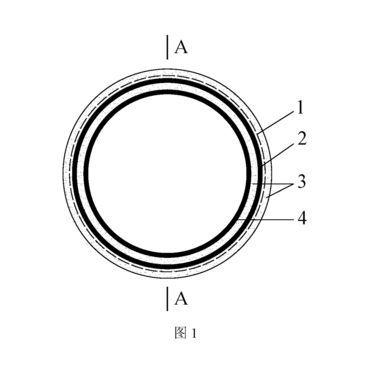

Production process: no steel reinforcing cage – normal casting and curing – then wrapping oft he pipes with a continuous tensile composite. Casting and curing process remains the same - but no reinforcing cage. Then, after normal curing, the concrete pipe is wrapped according to the Flexstren Technology.

The pictures show a DN600 Jacking pipe that after wrapping will be able to take 10 bar internal pressure (14 Bar testing). The pipe has 130 mm wall thickness and is capable to taking 1800 Ton of jacking push vs. the 600 Ton when unwrapped. Wrapping material cost is about 12 EUR per linear meter for this application.

The Flexstren technology

The generated compression is bi-axial. The process is applicable to many concrete products, even from immediate stripping process where is it very difficult to apply prestressing and where traditional post tensioning is difficult due to geometry, cost, and the intrinsic limited productivity. While this is a quite revolutionary method, there are ASTM, ACI and ISO specs for appropriate calculations. These basically follow the FRP prestressing and post tensioned reinforcement method.

About existing usage of concrete and FRP

Most of the fibers and FRP rebars currently in use as reinforcement for concrete, have a much lower Young’s Modulus vs. steel and in many cases just slighter higher than concrete. Because of this the concrete cracks with very modest reinforcement stress making FRP very expensive vs. traditional steel reinforcing if the crack size is what is driving the structure sizing. This is typically the norm worldwide.

FRP rebars are produced by pultrusion which is a method that is not very effective on the medium and large rebar sizes, the sizes the market is normally requiring. This low efficiency is not related to production volume but is actually related to the pultruted product specific stress capacity. Basically, the large rebar sections are experiencing up to a 60% drop in the stress capacity.

In case of dispersed fibers, the situation is even worse since most of the fibers are not oriented to the concrete product tensile stress and when the dosage exceeds a relatively small percentage, the concrete becomes difficult to be placed and handled. As we know, high strength fibers have a cost per Kg that is much higher than steel and magnitude of times higher of any concrete component and admixture.

CO2 savings and approach

The approach is basically to use the least amount of fiber as possible. To achieve this, we use it in tension, transforming the fiber’s low Young’s Modulus from a disadvantage to an advantage. The fiber is 100% oriented in the tensile stress direction and the specific stress capacity of our formed FRP is significantly higher than what is possible to achieve with pultrusion or any other method for produce FRP rebars.

Flexstren reduces enormously the CO2 footprint since it impacts various aspects:

Lower material cost provided by a reduction of the thickness;

Composites have lower CO2 footprint versus steel reinforcement.

Wrapping machine and composite

The wrapping machine wraps in diagonal in order to induce both a radial and longitudinal post compression. The composite material is easily purchased locally, and consists of fiber (can be 2 types: glass or basalt fiber. Basalt fiber is more expensive, and completely unassailable from the chemical point of view) and resin.

FSC can provide the calculation of the composite needed, and also can provide the support to the customer’s engineering to calculate it by themself.