New technologies for precast concrete industry developed

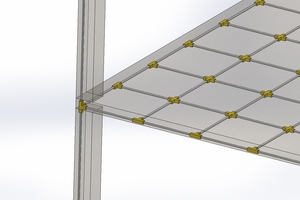

FSC Technologies LLC has developed new technologies for the precast concrete industry. The new bi axial post compression method for large paver slabs is a patent pending technology, applicable to large slabs from vibro compression process enhancing the product flexural behavior and eliminating the risk of unpleasant installation/use surface cracks which are the slabs sizes limiting factor. The bi axial compression is realized by wrapping with a given tension around the slab thickness, a corrosion free composite material.

The applied post compression together with the wrapping containment, permit to contain bottom cracks to propagate up to the top surface keeping the slabs structurally and aesthetically functional also in case of high loads or bottom soil sagging even with contained slabs thickness.

The reinforcement equipment can be tailored to a wide range of productiveness.

Pressure Activated Tendons

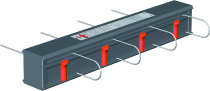

The concept is possible only using a composite structure since internal pressure to a hollow tendon is inducing hoop stresses that are twice the longitudinal. This high hoop stress limit the longitudinal maximum elongation making the technique not interesting if the tendon is a steel homogenous material.

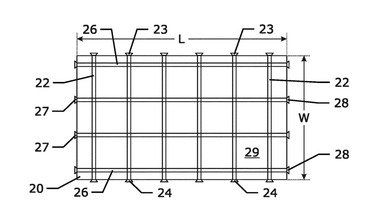

The tendons can be connected each other using connectors for generate a sort of cage. The reinforcing cage is pressurized increasing each single tendon length and eventually the entire cage along each direction the tendons are longitudinally oriented. Such stretched reinforcing structure will be placed in the mold and casted. Once the concrete cure enough to take the prestressing load, the pressure is removed, and the prestressing load applied to the concrete.

Once the prestressing is released to the concrete, are becoming an available network of cast in pipes in the concrete structure / part. In structural applications where fire resistance is a requirement, cold water could be circulated in those tendons generating an extremely efficient active fire protection system. In flooring application, the network could be used for cooling and heating purpose. In products like box culvert, the pipe network can be used as heat exchanger to soil for geothermal heating/cooling application or harvest the sewer heat.

FSG develops various patent pending applications about post compression of concrete products using composite materials. Most of them are focused on precast products from wet cast and immediate stripping process.