Functional hall for winery estate built with lightweight concrete elements

AT the beginning of 2018, a dream had become true for the May brothers: their new solid lightweight-concrete hall had been finished on schedule and now offered urgently needed space. “This is how an owner imagines a newbuild,” says Peter May. “Quick and uncomplicated, exactly as planned and agreed.” It was obvious that the project trio – consisting of the construction company Burgey, the companies E.L.F. Hallen and Thermodur – is a well-coordinated team.”

The newbuild was designed by the architectural office of Bessai and Klapper from Kindenheim, Germany. Jennifer Bessai, as the architect, is especially well attuned to the wishes of winemakers and to the special properties of Thermodur elements. She draws on the knowledge gained from several other vinification halls and wine storehouses designed by her, and she has often recommended the Thermodur system. Her clients’ expression of their satisfaction includes allowing her to use their projects in her reference portfolio.

Everything under one roof

The functional building for the Weingut May vinery estate was designed to accommodate several functional and utilization areas under one roof. The hall, measuring around 85 x 25 m, is divided into the vinification area with integrated laboratory room, the wine and bottle storage area, the wine tasting area, the social and sanitary rooms, and an enclosed area of the machinery park.

The Thermodur wall elements individually take functional account of the separate sections. In areas where air humidity is higher – due to frequent cleaning processes, mostly by steam-jet systems – the inner sides of the lower precast elements were coated by Thermodur in its plant with cement plaster. The joints were closed on site at the time the façade was completed, and the entire area was sealed with a waterproof coating.

In areas where the noise level is high, the inner sides of the walls of the façade elements were left as they are, with open-porous pumice structure, to enable maximum noise absorption.

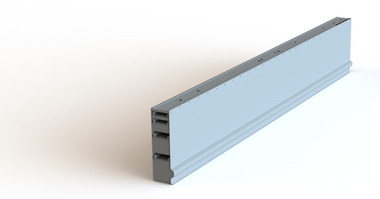

Elements with super insulation core

The section accommodating the machine park was closed off with lightweight concrete elements executed as fireproof separating walls of 22.5 cm thickness and a fire-resistance rating of F90. The remaining separating walls made of precast lightweight concrete elements were executed with a wall thickness of 20 cm. For the façades that protect from outside air and changes in weather, the elements were executed in a thickness of 37.5 cm with integrated super insulation core and a thermal transmittance of U = 0.28 W/m²K. this achieves maximum thermal insulation, resulting in a year-round balanced indoor climate – in winter, the interior cools down relatively slowly and heats up in summer likewise relatively slowly.

Built-in heat storage

The massive precast lightweight concrete elements for the interior wall have another very special advantage in that they serve as heat storage. This contributes to a uniform indoor climate and to slowly changing indoor temperature.

This particular property is unique to massive construction materials: such as, for example, precast lightweight concrete elements – which, due to their ability to store heat – are able to absorb heat and release it to the ambient air in cooler temperatures. Due to the heat storage capacity and the thermal insulation of the precast lightweight concrete elements, this process takes place slowly and by greatly reducing the intensity of the heat (i.e., the temperature difference.) This delay is also described as phase displacement.

Winemakers, fruit growers and market gardeners as well as all other agricultural enterprises – up to and including filling plants and food storage operators – greatly value this special property.