Thermodur produces wall elements more efficiently thanks to variable shuttering heights

Today like this, tomorrow like that: Manufacturers of façade elements must be able to respond to customer requests in a fast and flexible manner. Not rarely the shuttering height is the neuralgic point. Thermodur, the well-established manufacturer of wall elements made of (lightweight) concrete, was searching for a technical solution enabling the production of wall elements made of natural pumice in different thicknesses. Weckenmann meets the customer‘s specification with the M-Basis/M-Top series to the full extent and can tick off all points required by Thermodur.

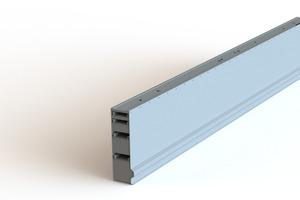

A central point of the specification was the fact that the new system should ensure a continuous shuttering profile with a length of 8 m so as to make full use of the pallet length. Apart from that switching between different heights should be done easily. Likewise on the very top of the list of desired features: The new formwork system should require little storage space – compared to those of other market players, according to the supplier – and it should be easy to handle even in narrow travel paths.

More flexibility thanks to variable shuttering heights

The solution of Weckenmann allows all this and can be used on both sides as a modular system with height extension profiles. With the specific solution that is optionally robot-supported, Thermodur has acquired an innovative formwork system that, in this case, is specifically designed for solid walls. Otherwise, the M-Basis/M-Top series prove to be diverse: It is possible to realize beam and solid elements, solid walls and sandwich panels and not least, special parts along with floor slabs and façades in changing shuttering heights.

Everything is possible between 180 mm and 510 mm as the total of four M-Top profiles can be used together, providing for an overall height of up to 510 mm. In principle, a total of 14 different combinations can be created using the four available M-Top profiles and thus ensuring more flexibility in the manufacture of wall elements. Handling is intuitive: The M-Basis profile comes with integrated magnets, which function as fixtures of the M-Top profiles after their positioning. M-Top profiles can be locked as well as unlocked easily, and transport is possible as package or separately. Manufacturers benefit from the continuous shuttering profile featuring a length of 8 m. If manufacturers have to meet infrastructural challenges, e. g., narrow radii, a special spreader beam leads to maximum relief, allowing for safe transport. Another plus: The Weckenmann profiles also convince in terms of storage by a reduced space requirement, thus freeing storage space for other resources.

Thanks to this individual solution for increasing the shuttering height, Thermodur once again obtains more flexibility in its production of large-sized façade elements and is able to extend the existing maximum dimensions of 11 x 3 m as well as wall thickness of 15 up to 40 cm by different heights.

CONTACT

Weckenmann Anlagentechnik GmbH & Co. KG

Birkenstraße 1

72358 Dormettingen/Germany

+49 7427 9493-0