Geothermal Segments: The Tunnel as Heat Supplier

In the course of the upgrading of the railway route from Munich to Verona, a part of a tunnel in the area of Jenbach in the Tyrol has been thermally activated. It now supplies geothermal energy to the nearby utility centre.

Thanks to the logging of data from the operation of the Jenbach thermal power plant since 2012, and also from additional tests, it is now possible to make more detailed statements about the energy potential and opportunities of energetic activation. The heat, which in this case is extracted from quite a shallow depth, is used for heating and cooling purposes in buildings and transport structures with a potential extraction rate of 25 to 40 W/m². It has been demonstrated that the payback period is of the same order as normal geothermal plants.

Introduction

Civil engineering structures in contact with the ground possess large areas that are suitable for the extraction of heat [1] [2]. This can be implemented in conventional tunnelling using an energy fleece or in mechanically bored tunnels by installing geothermal segments/energy tunnel linings [3].

Geothermal segments, a cooperative development by the companies Rehau AG+Co and Ed. Züblin AG (Zentrale Technik), were used for the first time in a 54 m long section of the 3.5 km long Jenbach Tunnel in the Tyrol. The first energy tunnel lining power plant in the world, the tunnel has been supplying geothermal energy to an operations building belonging to the local council since 2012 [4]. Since the commissioning of this pilot project, the temperatures of the segments, the tunnel, and the flow and return heating pipes have been logged, as well as the running times of the heat pump. This makes it possible to draw a direct comparison between the estimated heat output, which was determined for the dimensioning of the tunnel power plant, and the provided and requested heat energy in running operation. Questions about the following aspects are particularly interesting: Forecast versus delivered output; energy saving potential; cost-effectiveness; reliability.

In order to answer these questions, further background information is necessary about the system “Energetic activation of tunnels/segments” and particularly the already activated tunnel in Jenbach.

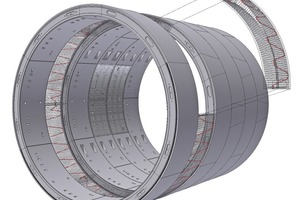

Activation of lining segments

In order to be able to geothermally exploit the tunnel lining consisting of segments, an absorber pipework system was integrated into the outer reinforcement layer of the segments (Fig. 3). Similarly to related solutions, such as energy piles, this variant is called energy tunnel lining. In Jenbach, the pipes in the individual segments are coupled at box-outs in the longitudinal joints to create a ground source collector surface of about 2,000 m² (outer tunnel circumference about 40 m) along 54 m of tunnel.

Since tunnels are designed for lifetimes of more than 100 years, it is important to use a correspondingly durable material for the pipework [6][7]. Pipes of pol-ymerized polyethylene (PE-Xa) can be bent to tight radii and possess suitable performance characteristics (for example Full Notch Creep Test), which are superior to conventional PE-HD pipes [8]. In this case an appropriate product made by Rehau, which has often been successful in geothermal applications, was used.

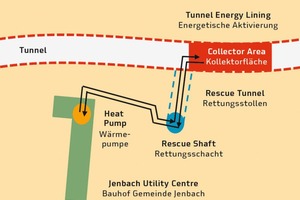

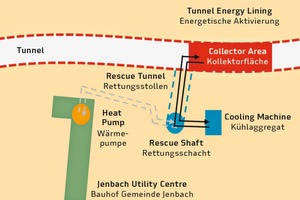

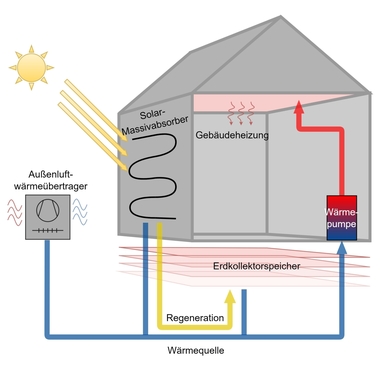

The heat absorbed by the heat transport medium in the tunnel is fed through pipework through the rescue tunnel to the rescue shaft and is distributed to the heat transfer station in the utility centre in Jenbach, which serves as the consumer for the extracted heat (Fig. 4). In order to quantify the heat extracted from the tunnel, the energetically activated section is equipped with measuring instrumentation.

Measuring instrumentation

of the Jenbach Tunnel power plant

The heat extracted through the heating circuit is determined by temperature sensors, which measure the flow and return temperatures in combination with the flow and material parameters of the fluid circulating through the pipework.

In order to be able to detect the effect of the heat extraction on the surroundings, additional PT100 temperature sensors measure the temperature of both the air in the tunnel and in the segment lining.

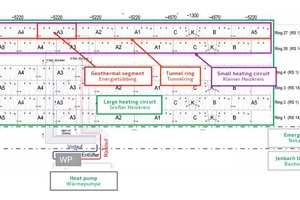

Several geothermal segments are assembled to form a tunnel ring (Fig. 2); a certain number of connected rings form a heating circuit according to the size of the tunnel (Fig. 5). In Jenbach, 13 heating circuits were connected to the overall collector area. The flow and return temperatures of the heat transport medium are measured by PT100 temperature sensors in the flow and return pipes of the small heating circuit to the distributor.

Dimensioning of the tunnel power plant

Tunnels are generally suitable for the effective application of heat pumps when both the tunnel and the soil temperature show an adequate difference from the ambient temperatures above ground. This makes it possible to use the tunnel for cooling in summer and for heating in winter.

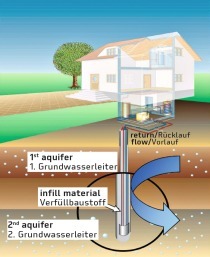

For the design of the geothermally exploited section of tunnel in Jenbach, the plant had to be dimensioned considering the demand from the consumer. First, a preliminary design was carried out using the Finite Difference Method (FDM). This process was however not able to take into account complex geometries, variation in soil parameters, interactions between the adjacent tunnel bores and directed groundwater flows. Stronger groundwater flows in particular can have a significant influence on the necessary energy input. Therefore the calculation inputs had to be chosen on the safe side.

Geological and hydrological reports were used for dimensioning in order to gain information about the soil parameters needed to estimate the extraction capacity such as thermal conductivity, density as well as any groundwater aquifers.

The section of tunnel activated in Jenbach is near the River Inn, whose riverbed is characterised by particularly permeable gravels and sediments. The aquifer is about 10 m away from the activated tunnel section. The tunnel temperature is about 12 °C, whereas the undisturbed soil has a temperature of about 10 °C. Only the ground around the tunnel was simulated (Tab. 1). The segment lining was not considered due to its thinness compared to the surrounding subsoil.

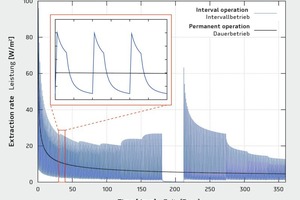

Two scenarios were considered (Fig. 6). In the first case, the average temperature of the absorber fluid was kept constant over the entire period under consideration, which corresponds to permanent operation of the geothermal plant over the entire year. This investigated scenario of permanent operation is practically unrealistic since the heating plant is only operated on a seasonal cycle. The calculation with permanent operation showed that the soil can be cooled throughout if the plant is operated for too long. Due to the long regeneration time of the ground, this can lead to increasingly reduced extraction rates.

In the second investigated case, the plant was dimensioned for cyclical operation. Only the number of hours at full load was considered, i.e. heat extraction was only simulated for a few hours a day depending on season.

If the results for interval operation are compared with those for permanent operation, then the plant has higher extraction rates during the operating time. However, this simulation also shows a certain cooling effect on the subsoil over the course of a year, so that the extraction output also declines slightly in this case.

Based on these calculations, an extraction rate of 10 W/m² was determined for the dimensioning of the plant, and then used to determine the required collector area. After the completion of the tunnel and the energetic activation of the section in Jenbach, the extraction rate in operation was determined.

Yield in operation 2012 to 2014

The relatively mild winters of 2012/2013 and 2013/2014 led to less heating demand in the operations building, which could be delivered without problems by the tunnel geothermal power plant. In order to optimize heating operation, the flow conditions in the absorber circuit were varied in a first series of tests. The circulation pump was adjusted to give laminar flow. The Reynolds number, abbreviated Re, is a dimensionless quantity, which characterizes flow conditions. Values of more than 2,300 are described as turbulent flow conditions, and values less than 2,300 denote laminar conditions, although in practice a transition range has to be expected. Reynolds numbers less than 2,300, due to the laminar conditions and the lack of turbulence, result in less heat transfer into the pipework and thus a lower extraction rate.

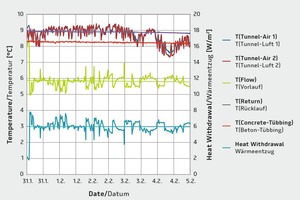

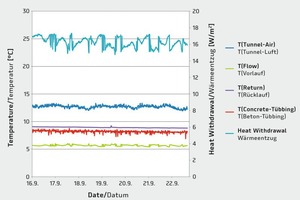

The series of measurements in this time period with Re from about 1,650 (Fig. 7) showed in practice a low settled temperature difference (about 3 K) between the flow and return of the heating circuits in the tunnel lining, which gave an extraction rate in the range 4 to 8 W/m².

This corresponds to the range predicted in the previous simulations. No cooling of the subsoil as a result of the required energy demand could be observed in the measurement series shown in Figure 7; so there is enough heat for this application.

Maximum yield

Of particular interest was the question, what quantity of heat would be available under the given hydrogeological and constructional conditions. This was investigated in the next series of tests by increasing the extraction rate, which was achieved by varying the flows and thus the flow conditions.

In order to ensure constant conditions for the individual test series, a cooling machine with circulation pump was connected directly to the flow and return near the collector (Fig. 8). This cooling unit could create an increased heat demand in continuous operation and also made it possible to hold the flow temperature of the absorber circuit constant in permanent operation. Tests with different temperature levels were also carried out. The supply to the Jenbach utility centre was interrupted during all tests.

The circulation pump enables the variation of the flow, and various flow conditions are possible depending on the flow. In the present case, the flow conditions are categorized as follows:

Laminar: Re number ≈ 1,200

Transitional: Re number ≈ 2,300

Turbulent Re number ≈ 4,200

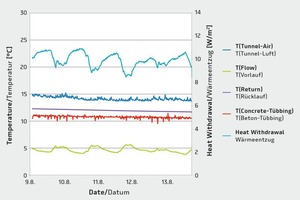

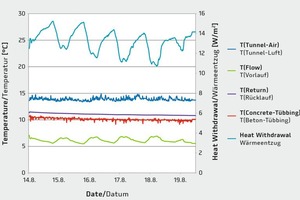

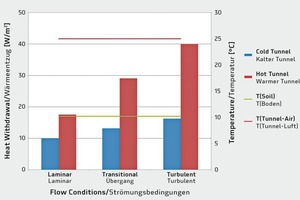

Each series of measurements was run for several days so that the effects of each flow condition on the sluggishly reacting ground around the tunnel could be measured. Under laminar flow conditions (Re numbers about 1,200), the heat extraction rate was about 10 W/m² (Fig. 9). With increasing flow velocity, this increased to about 13 W/m² in the transitional range (Re about 2,300, Fig. 10) and 16 W/m² under turbulent conditions (Re = 4,200, Fig. 11). The relationship between the flow and the heat extraction rate can be seen clearly from the results of the partial tests with different Reynolds numbers and flows.

The higher extraction rate was also noticeable in the temperature sensors of the geothermal segments. In the laminar range, the temperature was more than 10 °C (Fig. 9), whereas with a higher extraction rate and under turbulent flow conditions in the pipework, the temperature in the concrete segments was less than 8 °C.

Another good indicator of higher flows was the reduced spread (temperature difference between flow and return) in the heating circuit. This reduced from about 6 K under laminar conditions (Fig. 9) to only about 3 K in the turbulent flow range (Fig. 11).

The following observations were made:

The heat flow increased considerably with increasing flow (laminar – turbulent: +60 %).

Even with relatively high flow temperatures of 6 °C and cold tunnels, extraction rates of > 15 W/m² could be achieved. At lower flow temperatures with the associated higher temperature difference to the ground and the tunnel air, a higher extraction rate is thus still to be expected.

The activated section with a length of just 54 m is only a fraction of the total tunnel length of about 3.5 km. It is therefore possible that the slight lowering of the tunnel air temperatures in August and September was not caused by the activated segments but is associated with the lower air temperature outside the activated section (Fig. 9 to 11).

Cold and hot tunnels

The different local conditions and features of tunnels permit a simple classification into “cold” and “hot” tunnels regarding their thermal capacities:

Cold tunnels

The tunnel in Jenbach would be described as the cold type. Characteristic for this type of tunnel are their relatively low air temperature of about 15 °C all year round, a moderate cycle frequency of trains passing through and low energy input, for example from braking trains, that cannot significantly increase the temperature in the tunnel [5]. This type of tunnel normally has a large internal diameter in the range 10 to 12 m. The prevailing temperatures in the tunnel only have a limited effect on the temperature in the surrounding ground. Road tunnels can also belong to this category.

Hot tunnels

Hot tunnels, on the other hand, usually show high summer temperatures of about 30 °C [11]. These are mostly urban tunnels (underground railway) with typical internal diameters of about 7 m. Numerous stations and a rapid cycle frequency of trains lead to additional heat input from braking and starting [5]. This increases the air temperatures in the tunnel, which warms the ground [12].

Extraction rates in hot tunnels

Due to the high temperatures available in hot tunnels, the determination of extraction rates for this type of tunnel seems promising. Particularly considering the increasing traffic volumes and the associated further extension of underground rail networks in large cities, there is a large energy potential for exploitation.

Using the same soil parameters as the calculations for the Jenbach Tunnel and with the specified values of tunnel air temperature of 25 °C, a soil temperature of 10 °C and a constant flow temperature of 5 °C, the heat extraction rate ranges between 18 and 40 W/m² (Fig. 12). The heat extraction rate is determined depending on laminar (Re ≈ 1,200), transitional (Re ≈ 2,300) or turbulent (Re ≈ 4,200) flow conditions. The temperature of the air in hot tunnels (metro tunnels) in the stationary case is calculated from the summer temperature of about 30 °C and the winter temperature of 20 °C. Experience shows that the tunnel air is on average 10 K warmer than the surrounding ground [12].

The calculated values are shown in Figure 12 in comparison with the values measured in the cold rail tunnel in Jenbach. This comparison makes clear that extraction rates from hot tunnels with turbulent flow conditions and higher flow rates are more than twice those from cold tunnels. Due to the higher temperature levels in hot tunnels, for example, laminar flow conditions from Re numbers of about 1,200 are already sufficient to achieve similar extraction rates to those from cold tunnels with turbulent flow conditions (Re numbers of about 4,200). Due to the lower pressure losses, this has a positive effect on the pump power required and the operating costs.

Cost effectiveness of geothermal segments

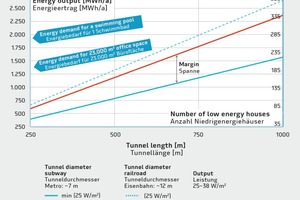

Then the cost-effectiveness of energetically activated hot and cold tunnels was also considered. A flow temperature of 2 °C was assumed in order to create a greater temperature difference between the fluid, the surrounding material of the ground and the tunnel air. This is advantageous for adequate heat extraction, particularly for cold tunnels, and permits similar extraction rates with lower flows/Re numbers compared to the measurement series (Fig. 12). The parameters used for the cost-effectiveness study are shown in Table 2; the quantity of energy extracted can be better understood by comparing a few typical consumers (Tab. 3).

With an annual operating time of 2,196 hours, for example, the activation of a 500 m long “hot” metro tunnel can provide extraction rates of 25 to 38 W/m² and cover the energy requirements of 100 to 150 “KfW 70” low-energy houses (Fig. 13). In “cold” rail tunnels, the activation of a 500 m long section can provide extraction rates of 25 W/m² and due to the larger cross-section of the tunnel cover the energy demand of almost 185 “KfW 70” low-energy houses.

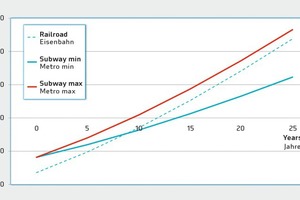

If the quantity of heat extracted from the activated section of tunnel is evaluated with about 0.06 euros/kWh (the experience of urban utilities in South Germany, 2014) and these earnings are offset against the investment costs, then a payback calculation can be carried out as shown in the diagram in Figure 14. Under the given conditions, the estimated payback time is between 9 and 15 years depending on the type of tunnel and extraction rate.

The consideration of cost-effectiveness also showed that the investment is only sensible from an activated tunnel length of 250 m if the heat energy is to be sold. If the heat energy is not sold but used to cover in-house demand, for example for the heating and cooling of operations rooms, platforms etc., then shorter sections of tunnel equipped with geothermal linings can also be economic.

Conclusion and outlook

Evaluation of measured and operational data over a period of more than ten months for the geothermally exploited Jenbach Tunnel showed a positive balance for the operating costs of the utility centre in Jenbach: heat extracted from the geothermal tunnel lining pays back the necessary investment costs in a similar manner to conventional shallow ground-source geothermal systems. The advantage of geothermal linings: geothermal heat can be extracted in areas where classic geothermal systems cannot be installed, such as densely populated inner-city areas.

As is shown by the practical experience from Jenbach, energetic activation of a tunnel section is thus a very good opportunity to exploit this freely available geothermal energy in order to save considerable heating and cooling costs. If waste heat from building cooling down in the summer is conveyed to the cold tunnel and into the surrounding ground, the energy can be used for winter heating operation. This additionally improves the cost-effectiveness. For cold and hot tunnels, the payback times are of a magnitude comparable with conventional geothermal applications.

Particularly tunnels in urban areas offer great potential for geothermal exploitation due to the presence of consumers in the immediate vicinity. If the energetic activation of tunnels is considered at an early stage of the planning of urban areas and the design of tunnels, such a system is easy to integrate into the design process.