Groningen decides on precast concrete bicycle tunnels

The local designation Aanpak Ring Zuid stands for a gigantic traffic project of great importance to the capital of the Province of Groningen in the Netherlands. Major volumes of traffic that previously used the 12-km long ring road south of Hoogkerk leading toward Euvelgunne will in the future be re-routed. The objectives are: improvement of traffic flow, better accessibility of the city, more greenery, and more traffic safety.

Groningen, according to a study by the Austrian Traffic Club VCÖ from 2013, is one of the most bicycle-friendly cities in Europe in terms of the volume of bicycles in day-to-day traffic. The citizens of Groningen cover around 31 % of their total traveled distance by bicycle. It is therefore only logical that optimization of bicycle traffic plays a significant role in planning the conversion measures.

Tunnel erected in only 48 hours

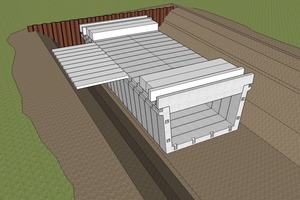

To ensure safe crossing of the railway tracks at the Esperanto intersection, the client, Combinative Herepoort, decided on construction of a tunnel for pedestrians and cyclists between Helperzoom and the Europark. To keep the necessary track downtimes for railroad traffic between Groningen and Assen to a minimum, the planners decided on a precast solution from the concrete plant Betonwerk Kleihues, in Emsbüren, Germany.

Dipl.-Ing. Paul-Martin Großkopff, Managing Director of Kleihues, explained the advantages of this construction method: “The Esperanto Tunnel is composed of 18 individual concrete elements, each including four end and threshold walls, as well as four derailment guard elements. Because we were able to work in shifts with two erection teams, each with four men, we were able to erect the tunnel in only 48 hours. The first trains traveled over the newly laid tracks only seven days after beginning of downtimes. Construction of a tunnel based on a conventional construction method would have taken significantly more time.”

Advantages of prestressing the precast elements

Utilization of precast elements, moreover, offered a number of additional advantages. Paul-Martin Grosskopff explained: “Owing to the trapezoidal geometry and the large clear dimensions of the tunnel sections (750 x 350 cm), the precast elements are sealed with a mortar joint and complete prestressing. During this process, ducts are built into the top floor and the base, through which, following erection, prestressing strands are threaded. These are then subjected to specified prestressing and are subsequently grouted.”

The advantage of this construction method, which is widely used in the Netherlands, can be explained as follows: in these often sandy sites, substrate not capable of load bearing is frequently encountered. By prestressing the precast elements, the entire tunnel acts as a beam on elastic bedding and is rendered significantly resistant to settlements and fluctuating groundwater levels. Delivery of the precast elements with a transport width of 4.90 m took place on a just-in-time basis. A 500-ton mobile crane then transported the precast elements, weighing approx. 46 tons, to the erection site.

Precast elements offer high quality

Another advantage compared to conventional construction is stated: “Precast elements are manufactured under controlled conditions and are subjected to continuous quality control,” explains Grosskopff. “This results in better concrete quality which also offers optical advantages in comparison to the in-situ construction method. Use of precast elements, moreover, requires significantly fewer work steps. This simplifies the entire construction project and consequently reduces possible error sources.”

The Esperanto Tunnel was built in August 2017. The overall Aanpak Ring Zuid is scheduled for completion in 2012. But one thing is already sure today: in the Esperanto Tunnel, cyclists will in future have the right of way – the trapezoidal shape of this tunnel moreover gives the tunnel a bright and friendly air.