The precast spiral – “De Helix” residential tower in Groningen

A tower and at the same time an example of good German-Dutch collaboration – constructive, goal-oriented planning and intelligent production methods and processing enabled the De Helix spiral in Groningen, Netherlands, a precast construction, to be quickly and successfully realized. The complete article incl. the construction panel can be read in the Betonbauteile Jahrbuch 2021.

A tower indeed it is: not a “Tower of Babel”, but an example of good German-Dutch collaboration. Constructive, goal-oriented planning and an intelligent production method, implemented with military precision, resulted in quick and successful realization of the precast construction, despite the cramped spatial conditions in the inner city.

As an up-and-coming university location with increasing attraction for students (47 % of the population is 30 or younger), Groningen is experiencing a growing need for affordable housing. Accordingly, an invitation to tender for an apartment complex near the inner city was issued as early as 2016. This competition, after careful consideration of environment issues and numerous design revisions, was in the end won by De Unie Architecten from Groningen with their tower. Architectural highlights of the nonagonal plan are the tiled façade pattern and the fully glazed common rooms on every floor.

Concept development

On the basis of the positive appreciation of precast elements, the precast plant Duha-Fertigteilbau GmbH Haselünne soon entered the discussions owing to its extensive experience in precast construction. In the joint discussions that followed, Duha presented convincing plans for implementation and construction. Accordingly, in mid-2018, the contract for the complete precast concept was awarded to the Haselünne precast plant. All precast elements for the tower approx. 70 m high were manufactured by Duha in Haselünne and erected within less than 12 months. The challenges posed by this project were of complex diversity: for one, the required construction resistance to earthquakes and tsunamis (the structural solution implemented was a piled foundation). An additional challenge was the architectural requirement for an exactly specified multi-colored tile pattern and, finally, the logistics in the cramped construction site situation. The latter issue stipulated construction without scaffolds and aerial platforms.

The initial plan had provided for a sandwich façade with clinker or queen closers. In the course of design discussions with the Duha precast plant, the solution increasingly developed to a genuine precast element with insulation, conduits, socket outlets, window frames and, finally, with an integrated tile pattern. Furthermore, all interior walls were executed as solid walls of 16 cm thickness, and the floor construction as perfect-fit slab elements, delivered by Duha. All utility supply lines were installed in the openings in the floors.

Production flow

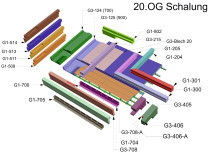

The individual sandwich elements measured 930 x 299 x 50 mm (L x H x W). Therefore, in the first step the production department accordingly prepared the production tables for installing the tiles. However, before installation of the tiles could begin, it was necessary to sort the packages containing the tiles, which the manufacturer had labelled with numbers. To prevent mix-ups, the numbers 6 and 9 were left out. In the next step, the tiles had to be allocated by number to the individual pattern of the wall. Finally, the tiles were installed in accordance with the pattern specified by the architects. In the next step, the reinforcing cage, fully welded in compliance with the stringent requirements, was installed in the face panel. For the window boxes, Styrodur openings were cut to size and installed, with sealing of the Styrodur ends. The face panel was cast with concrete C50/60. In order to satisfy the strict demands for thermal insulation, the Styrodur insulation was fixed in place with thermo-anchors. Next followed installation of the reinforcing cage for the supporting channel, installation of the conduits and the socket outlets and all other embedded parts. Casting, compaction and finishing of the supporting panel required special care. The specification for the interior side was for installation “ready for painting.”

The hardened precast walls were placed on inloader pallets. The next step was pointing. After this step, the walls were finally inspected and cosmetically reworked, if required, and cleared for transport.

Really complete precast elements delivered

The logistics had always called for one floor in production, one floor on call for loading and a third floor on the construction site. It was planned that the window fitter would fit and finish the windows with windowsills at the construction site. Because the situation on the construction site – as described above – was extremely cramped, it was decided, after the first window was installed onsite, to install the windows in the Haselünne plant.

The decision to carry out the individual comprehensive work steps in the Haselünne plant under nearly ideal conditions, independently of the weather, ensured the high standard of quality specified by the client and the architects. It furthermore untangled the situation at the construction site in the inner city and accelerated erection without scaffolding. On the average, one floor was completed every nine days.

A complete solution

As a complement to the apartment tower – giving due regard to the Dutch mobility habits – a “Fietsenkelder” (bicycle cellar) was harmoniously integrated onto the tower on the downward sloping terrain. There, Duha implemented an exposed-aggregate façade in crushed stone to match the outer staircase.

The entire precast solution with maintenance-free joints was completed within the short construction time from April 2018 to January 2020 and enabled fast utilization of the building complex. To realize the tower as a low-energy building, natural gas is used and, as a final step, a blower door measurement was carried out to check the airtightness of the building. That makes the Helix a truly outstanding building in Groningen’s urban landscape, not alone for its height.