Highly flexible pallet carousel plant for producing solid and sandwich walls at BWE-Bau in Lemwerder

In 2019, BWE-Bau Fertigteilwerk relocated its Wiefelstede production facility to Lemwerder. Avermann Betonfertigteiltechnik GmbH & Co. KG was contracted with manufacturing, delivering and commissioning the new production line. The mixing unit was sourced from Haarup Maskinfabrik, the Danish equipment manufacturer.

In 2019, BWE-Bau Fertigteilwerk GmbH, a member of the Zech Group, relocated its Wiefelstede production facility to Lemwerder.

Zech Group SE is a strategic management holding company serving as the umbrella organization for three divisions with their operating entities. This parent company coordinates the activities of the three divisions, develops the overarching strategy, and defines the global targets and objectives for continuously developing the entire group of companies. Zech Group is a medium-sized, family-owned and managed company whose wide range of services make it an experienced partner in the building, real estate and hotel segments. This broadly diversified group of companies focuses on the entire value chain in the real estate industry.

BWE-Bau produces a wide range of extensive precast elements, including solid walls and sophisticated sandwich façade panels as well as elaborate custom elements. The company primarily serves the residential segment, but the dimensions of the pallets used in the production process also allow for the manufacture of large-scale wall units for industrial premises.

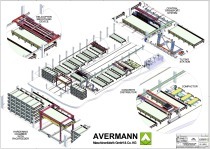

From a design perspective, it soon became clear that a state-of-the-art pallet carousel plant should be chosen as the new production line. BWE-Bau reviewed and assessed the range of carousel plants available on the market and finally opted for a highly flexible design with a central transportation system.

Plant design complete with production equipment

A suitable factory building was identified on the former Lemwerder airport premises, which Gustav Zech Stiftung partially acquired in 2018. Avermann Betonfertigteiltechnik GmbH & Co. KG was contracted with manufacturing, delivering and commissioning the new production line. The mixing unit was sourced from Haarup Maskinfabrik A/S, the Danish equipment manufacturer.

The production line is designed for a total of 25 pallets measuring 10.0 × 4.5 m and resisting a load of 7.5 kN/m². At the core of this highly flexible plant is the central transportation system (CTS) installed in the middle of the production line, between the individual work stations. The CTS transfers the individual pallets from one work station to the next. However, rather than being linked to rigidly defined workflows, such transfer routes can be chosen almost randomly in a “crisscross” pattern. Along its longitudinal route, the CTS is operated fully automatically (roto-scanners light the travel route of the system) and can accommodate two fully loaded pallets. In most cases, however, only one pallet is transferred and replaced with the pallet available in the respective work station. This process ensures extremely short changeover times, thus preventing long waiting periods. Work at the individual stations can continue immediately.

A concrete spreader equipped with two exchange buckets is designed for distributing standard concrete grades as well as SCC. The production line includes additional machinery, such as an oscillating compaction unit with the option of activating high-frequency vibrational energy, a turning station, and a power trowel.

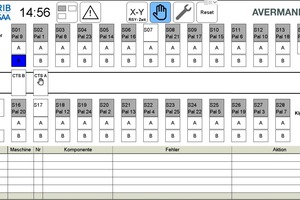

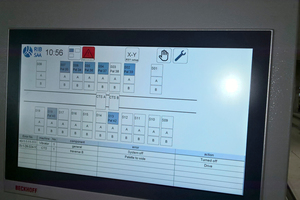

SAA control systems provide highly flexible operation and superior ease of use

RIB SAA Software Engineering GmbH, the Austrian provider, supplied the plant’s control and automation systems, which excel with their superior ease of use and flexibility. The central transportation system is operated fully automatically as a self-traveling unit. Pallet transfers can be preselected according to current production requirements. Again, the primary aim of this system is to optimize the transport sequences, which is why, in most cases, only one pallet is placed on the transportation system and conveyed to the target work station, where the second slot available on the system is used for transferring the second pallet back from the work station. As a matter of course, the system also provides the option of single-pallet transfers at any time. The central transportation system can be operated via a user interface on a touchscreen mounted on the CTS. Source and target can be easily selected by tapping on the screen, and the current status of the individual work stations is visible at any time, which greatly facilitates the exchange of pallets. Hitting the start button will prompt the system to automatically carry out the requested transfers. In addition, preselection is also possible from one of the fixed control panels located alongside the transport route. The transfer of pallets to and from the central transportation system follows the so-called dead man’s principle in order to comply with safety requirements at all times. As a matter of course, the system can also be easily switched to manual mode, plant surveillance and monitoring, or alert management directly via this graphical interface.

Being equipped with laser scanners on all sides for safety purposes, the central transportation system is capable of moving to and from its sources and targets in fully automatic, self-traveling mode. This operating principle leads to considerable time savings for shop-floor employees while also contributing to a generally higher safety level during plant operation. This system of work makes it possible to exchange pallets easily, safely and reliably while reducing operation time and effort to a minimum.

Mixing and batching unit

Haarup Maskinfabrik A/S, the Danish manufacturer specializing in mixing equipment, delivered and commissioned the mixing and batching unit. This unit has been optimized for producing high-quality concretes containing various types of aggregates, pigments and enhancers.

More specifically, Haarup’s scope of supply included a 15 m³ aggregate feed bin with hydraulic cover, a 50 m inclined conveyor with a throughput of 155 m³/h, 10 assembled aggregate bins (each providing a capacity of 60 tons and two replaceable day bins), as well as a distribution conveyor for these 10 aggregate bins. In addition, the equipment manufacturer delivered 12 batching conveyors, one weighing conveyor, four powder bins, each with a capacity of 60 tons, complete with the associated screws and cement weighers, and a 750 l and 1,500 l mixer providing a total throughput of about 34 m³ of concrete per hour. Moreover, the Haarup mixing unit comprises two four-chamber additive weighers, two pigment scales, two weighers for reused water, two bucket lines for conveying concrete to the Avermann spreader, 110 m of bucket conveyor tracks, and the complete MIXO 5000 control unit, as well as the complete assembly/commissioning process.

Conclusion and outlook

During the on-site interview with BFT editorial staff, the BWE-Bau plant manager, Dipl.-Ing. (FH) Wolfgang Ehrenberg, was very happy with the entire collaboration process as well as the outcome: “Right at the outset, during the first visit of the premises, we got a first impression of how the new production facility could look like. The extraordinary height of the building, for example, would allow us to install a curing rack in the course of the next plant extension, which also makes it possible to increase the number of tables. Today, I should say that this plant design is unique in Germany as it links utmost flexibility in the manufacture of custom façade panels with cost-effective cycles and process controls. We want to stand out from the bulk concrete market by setting a new standard with top-class products. To adhere to this high quality standard, our concrete is compacted on a unit that combines shaking with vibration. Last but not least, I am very pleased with the outstanding collaboration of all parties involved in this project.”

Johnny Lund Jepsen, project manager at Haarup, adds: “I can only reciprocate this compliment. The project was very well managed, and our customer, BWE-Bau, monitored and supported the entire process very closely.”

In the coming years, the demand for high-quality precast elements in a wide range of designs is expected to be very high. The prime strength of the pallet carousel plant is its high degree of flexibility that, for instance, allows for the simultaneous manufacture of components with a wide range of different processing times. Experience tells us that conventional pallet carousel plants usually reach their limits when it comes to this stage. BWE-Bau is now in a position to reap the benefits of an extremely efficient, multifunctional system for producing solid and sandwich walls as well as custom elements.

This endeavor is underscored by an impressive array of successfully completed projects, including, for instance, the Neuer Kanzlerplatz development in Bonn with a load-bearing precast external support structure, the “own” Zechhaus in Bremen featuring precast elements in reddish shades, and the Deutsches Auswandererhaus [German Emigration Center] in Bremerhaven. For the extension of the latter building, BWE-Bau delivered thin precast façade panels conforming to the German cast stone standard into which the portraits of 31 emigrants are imprinted.

CONTACT

BWE-Bau Fertigteilwerk GmbH

Flughafenstraße 6

27809 Lemwerder/Germany

+49 421 98508200

Avermann Betonfertigteiltechnik GmbH & Co. KG

Lengericher Landstr. 35

49078 Osnabrück/Germany

+49 5405 505-0

RIB SAA Software Engineering GmbH

Gudrunstraße 184/4

1100 Vienna/Austria

+43 1 641 42 47 0

Haarup Maskinfabrik A/S

Haarupvej 20

8600 Silkeborg/Denmark

+45 8684 6255