Horizontally arched box-girder bridges extended

Conversion work commenced in late 2016 to extend the width of the two existing horizontally arched box-girder bridges at the northern part of the Holendrecht expressway junction in the Netherlands. The project, according to the manufacturer, is regarded as unique because, as far as known, works of this kind are being executed here for the first time in the Netherlands. For the extension, Haitsma Beton delivered made-to-measure box girders, whose connection to the existing structures proved to be the greatest challenge of the project.

The extension of the A9 at Gaasperdammerweg in Amsterdam necessitated an enlargement of motorway junction Holdendrecht to ensure smooth traffic flow. For this purpose, among others, it was necessary to add traffic lanes for the two existing connecting arches that lead over the A2. IXAS Consortium – consisting of Ballast Nedam, Fluor, Heijmans, and 3i Infrastructure – is responsible for the execution of the project. This consortium enlarged section A9 between Holendrecht and Diemen.

Haitsma Beton had previously delivered precast girders for the new bridges for the A9 across the Gaasp River. The consortium once again coordinated with the manufacturer, beginning in the planning phase, for the current construction project.

Diverse requirements

Apart from cost constraints, additional factors such as construction time, environmental protection, and a minimum of traffic impediments had to be taken into consideration for the project. For that reason, demolition of the existing overpass and subsequent new construction were not options. Extension of the horizontally arched box-girder bridges proved to be the best solution – a first in the Netherlands.

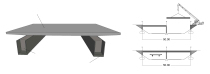

The solution involved employing box girders on both sides. The new elements can be structurally connected to the existing decking by means of a pressure layer. For the northern overpass, five intermediate supports will be provided, and for the southern overpass, six intermediate supports. The design of the supplemental structural members has been matched to the appearance of the original box-girder bridge. This results in very slender detailing with a height of only 800 to 900 mm, and with a maximum length of 26 m. The girders are also arched. In addition, the outer girders, which form the edges of the bridge, are sloped for aesthetic reasons. They will be subsequently provided with an edge element.

Precision work and

step-by-step erection

Connecting the box girders to the existing bridge and to the final arch turned out to be the greatest challenge. Owing to the small tolerances of the arches, precision work is essential here. The free space on the underside between the girders and the bridge will be provided with fiberglass-reinforced panels to achieve a flat slab. The extensive prestressing reinforcement is another crucial problem: it must be compatible with the small diameter of the structural members.

Erection of the horizontally arched girders began in late 2016. A total of six weekends is scheduled for this task, during which one part of the road network must always be available for traffic. The construction is scheduled for completion in mid-2017. “The works carried out so far have indeed been complex, but were completed outstandingly well. The curvature of the girders ideally matches the contours of the existing bridge decking. We can look back to successful weekend erection work,” says Haitsma Beton Project Manager Jasper Doornbos.