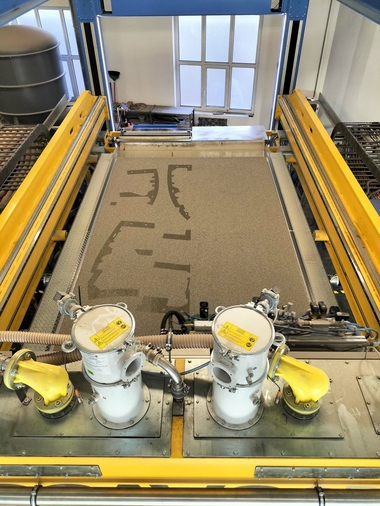

Innovation: 3D concrete printing head

According to the manufacturer, it is the world‘s first 3D concrete printing head for the selective paste intrusion method. Liquid Portland cement is injected through binder jet nozzles and the newly developed printing head in a coarse-grained sand bed, thus creating objects in any shapes desired.

In contrast to customary methods in concrete production, only a digital model is required here. By using the so-called Contour Crafting (an already known technique in concrete printing), it is not possible to bring concrete into an overhanging shape and thus elaborate supporting structures are required. The printing head developed by Metallconcept, on the contrary, allows printing of any three-dimensional shapes and objects in a completely free manner.

In January 2021, Metallconcept GmbH received the patent for this innovation after many years of research and development activities – inventor is Kurt Wohlgemuth, the owner of the above company. No grain of sand is wasted in the printing process because the required quantity is calculated exactly, enabling concrete savings of 30 up to 80 %. The manual and time-consuming labor in formwork operations – e.g., a staircase – is totally eliminated.

The field of application of the new 3D printing head for concrete is very broad and opens up many opportunities for the industry in terms of additional innovative products and techniques, e.g., the printing of complex architectural structures, entire planning on the computer including ducts for cables or pipes in building components and printing of the digital shapes directly by means of the 3D printer.

CONTACT

Metallconcept GmbH

Handwerkerzone 31

39058 Sarnthein/Italy

+39 0471 62 36 65