Innovation: 3D freeform staircase formwork

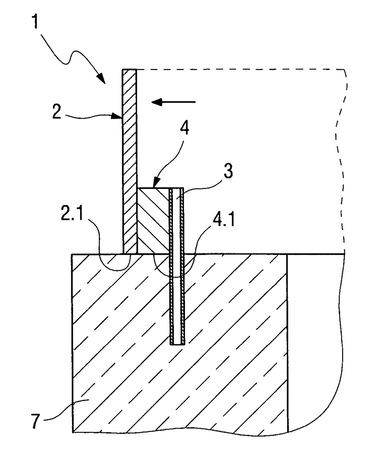

During recent decades, little has changed in production engineering of concrete staircase construction. Accordingly, around ten years ago, the idea was born to manufacture a staircase completely digitally – from planning to production. The result was the creation of the initial patented Scawo process based on CNC-milled EPS elements as lightweight permanent formwork. The formwork was subsequently provided with steel reinforcement installed in-situ at the construction site and cast with concrete. This process resulted in an environmentally harmful value-added chain – which involved utilizing a range of inorganic composites. Over the course of years, the wish arose for construction using fewer materials: i.e., for producing a staircase, if possible, with only a single material. In the following years, the first printhead for Sorel cement was developed in collaboration with various partners from research and development. However, because this material offers fewer possibilities of application than concrete, Metallconcept continued its research under the project name Scawo3D. By 2021, the worldwide first inkjet printhead for 3D-printed concrete was patented as part of the SPI method (Selective Paste Intrusion).

This technology now makes it possible to digitally plan and manufacture permanent formwork for any staircase form by modern form-finding and design software. This concept contributes to single-variety building by combining “like with like”: i.e. an end product is made available which, should the need arise, can be disposed of and/or recycled together with the surrounding building as conventional steel-reinforced concrete. The paradigm of single-variety construction is the focus of ongoing research, among other efforts, to find a solution for dissolving the permanent bond between concrete elements and reinforcement. By means of printed-in channels that, in the ideal case, follow the path of forces, it would be possible to eliminate time-consuming, cumbersome sorting after dismantling.

Initially solely developed for printing concrete staircases, the new 3D printhead opens up many other possibilities of application and, consequently, manufacture of a wide range of product and process innovations. Thanks to the similarity to conventional concrete and/or mortar and only minimal chemical modification of the 3D concrete, strength classes are achieved that, in terms of compressive strength, are equal to concrete types in accordance with to DIN 1045. Accordingly, depending on the granulation, 3D-printed freeform objects with strengths of up to C50/60 are possible. The result: 3D objects of any shape – loadbearing or non-loadbearing – which, in contrast to conventional production methods for concrete objects, require only a digital template for printing. Accordingly, there are no limits to the imagination.

CONTACT

Metallconcept Srl/GmbH

Handwerkerzone 31

39058 Sarentino/Sarnthein/Italy

+49 172 15 88 386