Innovation: CPC concrete slabs for the construction industry

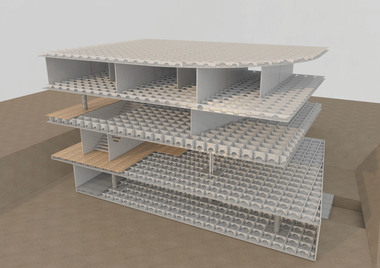

CPC (carbon prestressed) concrete slabs are based on a new technology that evolved from a long-term research project conducted by ZHAW and the company Silidur AG, in Andelfingen, Switzerland. The advantages of CPC slabs enable their numerous applications; first l projects in Switzerland have already been executed.

CPC slabs are reinforced with thin prestressed carbon strands. The very high tensile strength of carbon and the fact that carbon does not corrode enable the manufacture of thin loadbearing slabs. The previously required concrete cover of 3 to 4 cm to the reinforcement, as required for conventional reinforced-concrete slabs, is no longer needed. CPS slabs are three to four times thinner than conventional slabs and have the same loadbearing capacity at lower weight. The slabs excel under service load thanks to their great stiffness and freedom of cracks.

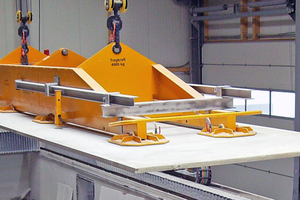

The company Silidur AG of Andelfingen manufactures the CPC slabs as semifinished slabs 2.3 x 10 m in size, with 2- and 4- cm thickness; customized slabs in other thicknesses can also be produced. Data for post-production proc-esses, for example, for making holes, cut-outs, depressions, surface finishes, and edge design are directly scanned from the digital drawing and are implemented in the processing system. The fine carbon reinforcement at the edges is hardly visible and there is no danger of corrosion at the cutting surfaces.

CPC slabs in building and bridge construction

Where low weight and high loadbearing capacity or manufacture for “perfect-fit,” among others, are essential, the use of CPC slabs in building construction can be of interest. Projects for reutilization of roofs (slab surfacing), stair structures or conversions using CPC slabs are in the pipeline.

In Winterthur, for example, a multi-family residential building was subsequently provided with balconies made with CPC slabs. The balcony slabs were premanufactured in the plant. The loadbearing steel construction was executed at low cost, due to the low construction height of the slabs and their consequently low weight and installation efficiently implemented.

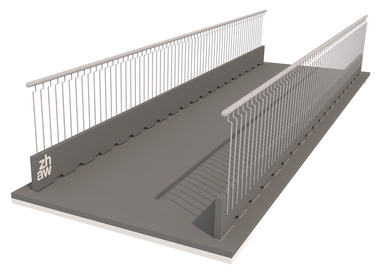

The Swiss community of Unterägeri, decided to pave the new boardwalk that was constructed within the scope of a project to redesign the lake shore, and the arch bridge over the Lorze River, which is listed as a historical monument, with CPC slabs. Thanks to the low weight of the CPC slabs, it was not necessary to strengthen the structure of the old arch bridge.

CPC slabs of 8 cm thickness were also used for the construction of a smaller bridge over a creek in Albisrieden in Zurich, which is traveled by agricultural vehicles weighing up to 18 t. The bridge was premanufactured of a single slab and installed in only one day.

CPC slabs for a wide range of applications

CPC slabs can be used for other applications as well, for example, in landscape construction. For the loads imposed on bicycle paths and pedestrian walkways a slab of 2 cm thickness is sufficient. Slabs subjected to vehicle traffic have a thickness of 4 cm. The surfaces of the slabs can be designed to suit almost any taste.

The CPC slabs are currently tested for use in the furniture industry, in kitchens, and for interior finishing. Numerous applications in garden construction are conceivable as well: pergolas, protective walls, benches, garden furniture, pavilion construction and more.