CPC – a new concrete construction method: Highly resistant plug-in connectors between CPC slabs

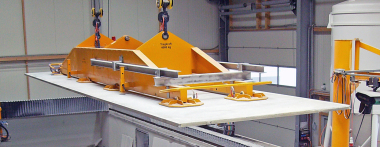

The CPC-Optima (CPC = carbon-prestressed concrete) modular bridge system is suitable for pedestrian and cycle bridges. This trough bridge design comprises a deck slab and two lateral beams. The beams and the bridge slab act as a composite structure and both consist of CPC60-4-4 slabs.

A friction-fit type of connection had to be developed to connect the two structural components, i.e. slab and beams, firmly to each other. This connection was to absorb tensile and compressive forces as well as bending moments and longitudinal shear while being robust and metal-free and providing long-term resistance to external actions.

A master’s thesis and a research project provided the basis on which a mortar-filled plug-in connector was conceived that eliminates the need for steel parts and adhesives. Structural analyses and experimental tests proved the feasibility of the connector. Its load-bearing capacity is surprisingly high so that it can also, quite unexpectedly, fully absorb the horizontal loads stemming from the side railings.

The connector system allows for bridge spans of over 15 m and deck widths of over 2.0 m.

The bridges only include the 60 mm thick deck slab and the lateral beams. The minimum beam height varies in accordance with the span. The deck slab can be installed in a slightly curved design elevated at mid-span. Railings are easy to bolt to the deck slab or the beams.

The abutment is very easy to design and install thanks to the low weight of the bridge and the durable, non-corrosive materials used for its structural components and connectors – only a CPC abutment slab placed on a frost-resistant sand and gravel subbase is needed.

This design results in a very robust and long-lasting bridge with an exceedingly small carbon footprint and maximum flow-through or clearance profile under the bridge.