Rethinking precast: Building construction using ultra-thin CPC slabs

Amid increasingly complex requirements for construction materials and products, building material producers are undergoing a transformation to become system suppliers while developing innovative products. CPC components provide an outstanding solution that combines many innovative approaches. CPC stands for “carbon prestressed concrete,” referring to precast components manufactured with prestressed carbon reinforcement.

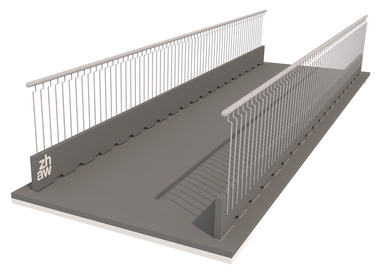

These slender yet highly resilient elements are suitable for a wide array of applications in construction and landscaping. To date, they have been used primarily for bridge decks and balconies. However, the range of possible uses – from mass production to custom solutions – is enormous and easy to implement thanks to the national technical approval granted to this technology: Modular bridges, stairs, foundation slabs, and façade panels have already been installed using CPC elements.

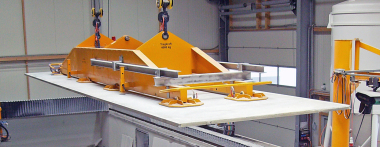

CPC slabs are manufactured in a fully automated process, and finished products are milled from the solid slabs with high precision. This setup makes it possible to decouple the manufacturing process from the finished product, establishing a fully automated, end-to-end production chain encompassing design, installation, and deconstruction. Slabs are produced with a 1 mm thin prestressed carbon reinforcement that eliminates the need for steel. Carbon does not corrode and has an extremely high tensile strength. It reduces the weight of the very thin, load-bearing concrete slabs to a quarter or a third compared to conventional steel-reinforced slabs. Prestressing keeps the slabs free from cracks even in loaded condition. The concrete used for the slabs contains a low-clinker cement; it is extremely resistant to frost, de-icing salt, and wear. The exceptionally long tested service life of 100 years is just one indicator of maximum sustainability.

In addition, CPC allows for material savings of up to 80% while reducing the total carbon footprint by up to 75% compared to similar methods using conventional steel-reinforced concrete. CPC elements are also easy to disassemble for ensuring their appropriate reuse. Their environmental impact has been documented in product-specific EPDs, and they were awarded the Cradle2Cradle Bronze certificate.