Innovation: FL-SEDI-Scan

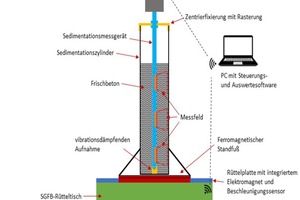

The potential consequences of an unfavorable combination of inappropriate mix designs in combination with faulty construction may lead to serious problems. At the new construction of the Wusterwitz sluice at the Elbe-Havel Canal, it was revealed during ongoing construction works that the concrete used did not meet the requirements and therefore had to be replaced. Sedimentation-prone fresh concretes of SCC and ECC grades are to be recognized with the aid of the new SGFB test technique consisting of a sedimentation measuring rod, a sedimentation cylinder and a vibrating table. This time-saving method recognizes and records defects still on the construction site, so that counteracting measures can be taken before pouring the fresh concrete. The time-resolved testing system used for a so-called SGFB test method is a development of the University of Stuttgart, Form + Test Seidner & Co. GmbH and Franz Ludwig Gesellschaft für Mess- und Regeltechnik mbH and is jointly supported by all three parties.

The sedimentation measuring rod is the prerequisite for the SGFB test method

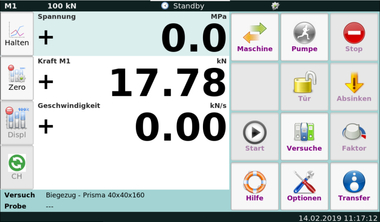

The microwave measurement technique consists of three sensors enclosed in a stainless steel rod. In contrast to the three-cylinder test, an elaborate and time-consuming washing-out procedure of the concrete sample is no longer necessary. The sensors positioned at three height levels in the fresh concrete cylinder allow characterizing the sedimentation behavior without considerable expenditure of time. The sensor is equipped with a lithium-ion battery, ensuring easy handling. The control and evaluation electronics refines and analyzes the measurement results with the aid of modern filter algorithms. Inside the sensor a WLAN access point is situated for allowing reading and documenting the results on a tablet or laptop. Another important component of this development, apart from the sedimentation measuring rod and cylinder, is the transportable, frequency- and amplitude-controlled vibrating table whose task is to compact the concrete and enable reproducible measurement results. The supplier promises that its product will measure and document the sedimentation behavior in a modern system, ensuring huge time-savings and efficiency. The new test method can be used standardly before the pouring of concrete.

CONTACT

Ludwig GmbH

Budenheimer Straße 1

55124 Mainz-Gonsenheim/Germany

+49 6131 91046 0