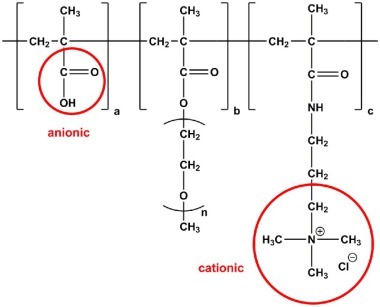

Innovation: MasterEase – superplasticizers for low-viscosity concrete

BASF launched the MasterEase range, a new generation of superplasticizers based on a new compound specially designed for low-viscosity concrete. This innovative type of superplasticizer improves the rheological properties of fresh concrete by reducing its viscosity whilst retaining its yield limit. For instance, in the conventional slump test of self-compacting concrete, this means that concrete to which a MasterEase superplasticizer is added will exhibit the same slump flow (diameter) at a similar superplasticizer ratio whilst requiring a much shorter time (t500). Moreover, the superplasticizer’s enhanced molecular structure enables more effective incorporation of ultrafine constituents such as fly ash. The above characteristics thus result in highly flowable yet stable mixes.

In a real-life environment, these beneficial properties become particularly apparent when producing and pouring binder-rich concrete systems with low water/cement ratios, such as ECC/SCC and high-performance mixes, which are often said to exhibit “high stickiness”. The MasterEase superplasticizer range significantly facilitates production, pumping, placing and finishing of such concretes since mixing times are shortened and transport is made easier (pumping pressure levels can be reduced by up to 20%). Furthermore, pouring concrete into the formwork or discharging it from the mixer takes less time, and the risk of defects or faults due to complex element shapes and high reinforcement ratios is reduced significantly. Mixes are generally more robust and stable, and the concrete’s low stickiness considerably facilitates the finishing and troweling process, thus increasing both production cost effectiveness and finished product quality.

The continuous improvement of innovative superplasticizers provides precast producers with a sound basis for manufacturing high-quality products efficiently and safely.