New technology for concrete with low viscosity introduced

The new MasterEase product range is now also on the market in Austria, Germany and Switzerland. It ensures excellent rheological properties for high-performance concrete and guarantees both a low viscosity and high stability of the concrete mix. In addition, it simplifies the pumping and placement of the concrete.

Dr. Jan Klügge, Head of Marketing Ready Mix Europe, explained the benefits of MasterEase to more than 100 invited guests at the legendary Panzerhalle Salzburg: “The ability to reduce the addition of water even further without compromising the concrete rheology means that there is new potential for improving the concrete formula: a lower water content in concrete mixes results in higher quality and improved durability.”

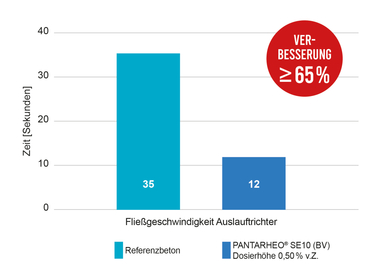

Significantly lower V-funnel flowtime thanks to MasterEase

Thomas Strobl, who is responsible for the technology and services of concrete admixtures in Austria, demonstrated the advantages of the new technology on stage with his team. Two concrete mixtures were compared: one contained MasterEase, the other a conventional PCE-based superplasticizer. A camera team accompanied the experts on stage so that visitors could have a close-up view of the tests on the screen. When comparing the V-funnel flowtime, the mixture with MasterEase had a significantly lower flowtime of approximately 11 seconds – the traditional superplasticizer took 24 seconds. When comparing the slump, there was no difference between the two mixtures.

After the demonstration, the participants were able to personally experience the quality of the new technology and test the concrete consistency with a stirring ladle: it was an opportunity that hardly any guest passed up. To this point, Jan Klügge has received very positive feedback: “Our customers have already used this new technology for architectural and civil engineering projects. The feedback was excellent: Especially in difficult concrete mixes that are optimized for sustainability, the pumpability is improved and the installation becomes much easier.”

New products for 150-year anniversary

For Philipp Kley, Head of BASF Construction Chemicals Europe, the new technology shows the advantages of close customer collaboration: “For us, it is very important to have an eye on the market and to develop our solutions together with the customers. With MasterEase, we have brought a product on the market that addresses these needs and makes it possible to overcome challenges that have been faced in the field of concrete rheology.” In looking back at the 150-year history of BASF, Philipp Kley illustrated that strong customer relationships are part of a long tradition in the company.

To mark the anniversary year, guests had the opportunity to inspect the various stations in the hall and get an idea of the wide product range of BASF. For Philipp Kley, the company‘s future lies in new innovations: “With our expertise in chemistry and the global network of research teams from Master Builders Solutions, we want to continue to offer the most advanced products on the market so that customers continue to have new ways to realize their projects.”