Innovative prefabricated timber-concrete composite

elements with adhesive bond

Adhesively bonded timber-concrete composite structures open up a wide range of new opportunities with respect to achieving a high degree

of prefabrication while ensuring efficient and resource-saving

material consumption and optimizing the construction process. Such hybrid load-bearing structures favorably combine the two materials in order to fully utilize their properties since concrete is predominantly subject to compression while wood primarily absorbs bending moments and tensile forces. In new buildings, using precast reinforced-concrete components is associated with a number of advantages compared to cast-in-place concrete because the high degree of prefabrication common in timber construction can be maintained while making full use of the benefits of concrete.

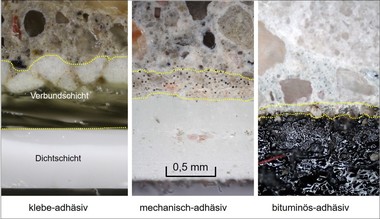

In a current research project, viscous polymer-modified mortars containing a thixotropic agent were found to be particularly suitable

for creating an adhesive bond because their rheological character-

istics compensate for the production-related unevenness of the precast concrete surface while developing sufficiently high adhesive forces and thus creating a full adhesive bond. Comparing different

surface textures (smooth formed finish, sandblasted, bush-hammered,

exposed-aggregate) revealed only a negligible correlation between

the bond strength and the type of concrete surface. It was also found that precast elements of strength class C45/55 (CEM-52.5R, maximum aggregate size 16 mm) with a smooth formed finish are capable of transferring bond stresses in the range of the shear strength of the timber.

This performance eliminates the need for a relatively comprehensive post-treatment to prepare the surface for application

of the adhesive while also saving costs. However, achieving a durable

adhesive bond essentially requires the contact surface to be free of release agent residues.

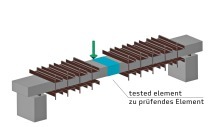

The research currently being conducted at the University of Kassel

concentrates on testing reliable and cost-efficient production processes

as well as developing methods for verifying the durability of the adhesive bond.