Activated clay – Grinding makes all the difference

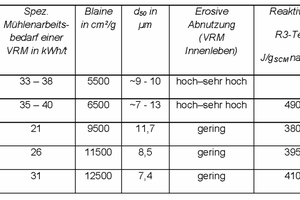

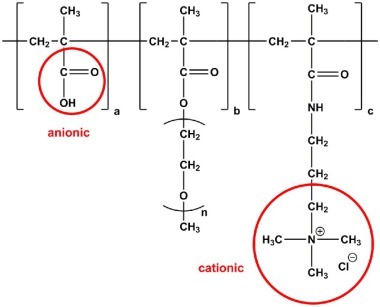

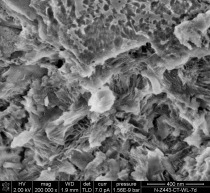

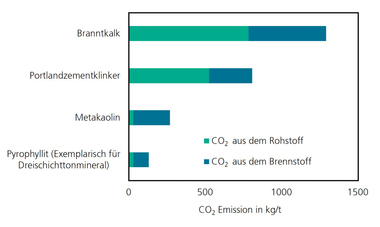

Calcined clays will soon present an attractive opportunity to produce concretes that are optimized in both environmental and engineering terms. This will provide the construction industry with a versatile yet sophisticated material for a wide range of applications in concrete technology. Critical to the successful use of calcined clays is their processing, which includes calcination and grinding. To date, only a few studies have been conducted that investigated the effects of grinding on the properties of calcined clays. This is, in part, attributable to the fact that there are hardly any industrial production facilities for clay calcination. As a result, materials are not available in the quantities required for industrial-scale grinding tests. However, the grinding process has a significant impact on the reactivity and performance of calcined clays. The first part of this presentation refers to tests carried out on calcined clay granules at a pilot plant of Gebr. Pfeiffer using a vertical roller mill (VRM). In addition to the findings obtained for the grinding process (specific power consumption, wear rate of grinding parts), the results related to the material (fineness, physical characteristics, and reactivity) will be discussed and compared with empirical values established for conventional supplementary cementitious materials. The second part of the presentation provides in-depth insights into the option of thermomechanical activation (i.e. grinding and calcination merged into a single-stage process), which was tested for different clays in a ZIM project conducted jointly with research partners Gebr. Pfeiffer, Institut für Werkstoffe des Bauwesens and TBS Transportbeton. Incomplete dehydroxylation of the phyllosilicates contained in the clays proved to be a critical parameter affecting both the performance and the durability of the concretes and producing properties not previously known from calcined clays.