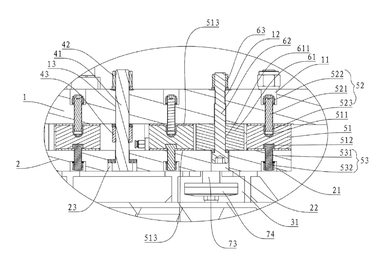

Interview: Precision surfaces, high color fidelity

The mold manufacturer Rampf has developed a coating system for tamper show surfaces. Sonja Schöntauf, on behalf of BFT International, talked with Rampf’s Managing Director Dr.-Ing. Peter Dauben about the properties of this innovation.

Sonja Schöntauf: Dr. Dauben, Rampf Formen GmbH introduces a new coating for tamper shoe surfaces to the market. What, exactly, is that?

Dr.-Ing. Peter Dauben: The manufacturers of high-quality concrete blocks have been grappling for decades with high reject rates, due either to voids in the blocks caused by concrete sticking to the tamper shoes, or...