Pre-design and experimental investigations

Road and pedestrian bridges are commonly built as cast-in-situ, prestressed reinforced concrete structures, but this method is both expensive and time-consuming. The installed reinforcing and prestressing steel requires a high concrete cover to ensure corrosion protection, which results in massive members. Nonetheless, it is often impossible to prevent corrosion damage to the steel reinforcement, such as caused by penetration of chlorides from de-icing salt into the concrete. The associated loss of bearing capacity as well as visual or aesthetic deficiencies require expensive, labor-intensive refurbishment or even reconstruction.

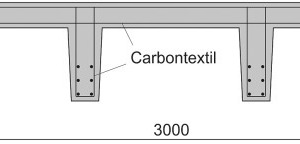

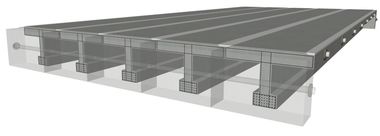

To overcome these drawbacks, a modular footbridge system with fully non-metallic reinforcement is being developed as an innovative solution to build durable footbridges in a cost-effective manner. The application of a non-corrosive carbon fiber reinforced polymer (CFRP) as a mesh fabric and pre-tensioned reinforcement is suitable for building slender, long-lasting elements. High-strength concrete with a dense, fine-grained matrix is used for the purpose of enhancing durability and reducing costs, which eliminates the need for additional pavements. The modular construction method enables fast assembly and disassembly of the footbridge.

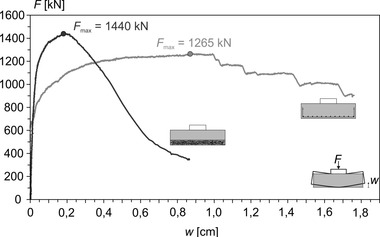

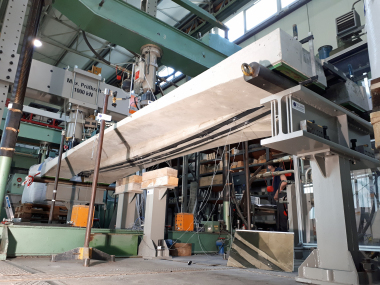

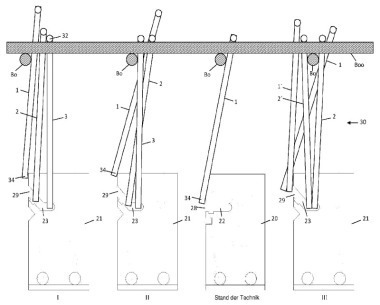

This paper outlines the dimensioning and pre-design of the cross-section of the footbridge system (see Fig.) whilst particularly considering the modular approach. Furthermore, the results of experimental investigations of the bearing capacitiy as well as bond behavior of the carbon reinforcement and the CFRP tendons are presented.