Iso-Matic 2.0 – high-precision cutting of insulation material (Video)

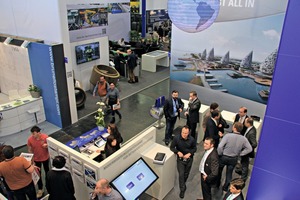

There is a strong demand for energy-efficient precast concrete elements, such as insulated double and sandwich wall elements, across the world. The cost-effective production requires new technologies, so as to be able to manufacture large production outputs of high-quality walls even in tightly organized processes and short time frames. At the Bauma 2016, Vollert Anlagenbau presented an improved version of the Iso-Matic work station, which they had already introduced at the Intermat 2012; Iso-Matic 2.0 allows for precise, automated cutting of insulating material for double and sandwich wall elements in any geometrical shape desired (bored circles, angles, waves and much more), while saving time and personnel expenditure and reducing material waste.

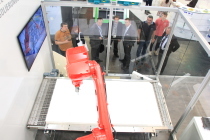

The Iso-Matic software imports existing CAD data via any industry standard interface, thus providing the component dimensions for the precise cutting of any shape in various insulation materials, as EPS and mineral wool. Then, the Iso-Matic generates the required cut from this information fully automatically. Customer-specific basic settings such as insulating panel thickness, clearance and type of the connection anchors and others can be integrated easily.

The actual cutting process is carried out by a 6-axle cutting robot operating at axle speeds of 175° to 360°/s and high position repetition precision. The precise water jet cutting head using 4,000 bar is forming the insulation material into the 2D or 3D shapes desired.

According to Vollert Anlagenbau, it is possible to integrate the Iso-Matic 2.0 into existing production plants without any problems.