Klebl and Dicad – no BIM without process

integration

The medium-sized precaster Klebl has been placing it’s the focus on digitization and BIM for many years, so much so that an independent business unit for logistics was created in the company. Bernhard Heilmeier, Head of the Department Application and Processes talks about his experience in structural design, reinforcement and formwork planning.

The Klebl Company Group is a medium-sized family enterprise for construction, structural precast components and trade, which is based in Neumarkt in the Upper Palatinate region of Germany. It employs a workforce of around 1,300. With its six precast plants, the company is the largest manufacturer of structural precast components in Germany. The business unit Klebl Building Logistics includes, among others, the areas of modular formwork construction, central machine logistics, concrete development and production, IT, sizing and quality management. Bernhard Heilmeier heads the Application and Processes Department in the company.

Digitization and BIM as opportunity

In step with progressing digitization in construction, Klebl develops processes and methods for cooperative fully media-compatible and cross-company BIM processes, without media discontinuation, to keep pace with the continuously increasing requirements of the market. The fact that 2D drawings still dominate in precast plants and on construction sites is no contradiction to Bernhard Heilmeier. “That will not change for the foreseeable future” Heilmeier is convinced. “It is not the question of whether 2D or 3D is crucial for me: rather, optimization of business processes.” Heilmeier illustrates this with an example: “In the past, formwork and reinforcement drawings, layout plans and detail drawings were prepared separately, without interconnection. Changes on one component formerly required complex updating of all planning documentation.

BIM automates these workflows and makes them more efficient. More intensive communication with project planners and the client ensures early compliance and fewer errors.” Because digitization and BIM are regarded as an opportunity, and since the added value has been recognized at Klebl, all structural designs are by now performed in 3D, regardless of their size.

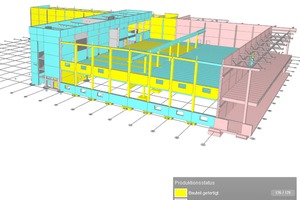

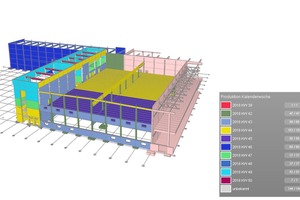

Own department for digital building

A prerequisite of BIM is that all existing processes in the company are examined and changed if necessary. At Klebl it was quickly recognized that there can be no BIM and no digitization without changes. This is why a new Department for Digital Building was established within the scope of BIM introduction. There, all internal and external BIM requirements were defined and the corresponding information integrated into the 3D models. For Klebl, integration of BIM in the production process is in the foreground: “Our planning, control and monitoring systems access the BIM model information and generate production and erection plans from it. They also show the current planning status and control production. By linking our 3D models with the fourth dimension of time, we obtain 4D planning with which we run construction flow and prognosis simulation. When merging the individual technical models from the various planning disciplines and checking for possible collisions, we can recognize possible problems early on and solve them.

Although the company has achieved a remarkable degree of digitization, Heilmeier is always in search of further optimization possibilities. “We constantly and intensively deal with the problem as to what extent we must adapt our processes, in order to utilize the added value of a 3D model as efficiently as possible in all project phases.”

First experience with the BIM funding project

The first experience with BIM was rather sobering. The company gained this experience at its Ingolstadt Office Center, in Germany, a BIM funding project (BIM reference project for Germany), which in 2015 was presented within the context of a technical symposium in Braunschweig, Germany. New construction of a three-story office and business building was involved here. Collaboration with the company pbb Planung + Projektsteuerung GmbH defined what information the individual BIM components in the model should have. The various viewpoints and interests in this initial experience soon became evident, explained Heilmeier: “Whereas pbb placed emphasis on cost approaches, Klebl concentrated on production of the structural components. Therefore, we quickly recognized that packing everything into one model is neither possible nor does it make sense. We would therefore have to link the structural components within separate technical models to the respective attributes of the structural components.”

However, the data volume of the individual technical models still quickly grew and data exchange became possible only by means of project platforms. In addition, there was the tedious problem of the interfaces. Because in-situ-concrete planning and structural analysis for the structural precast components were performed with different software systems, different data formats had to be exchanged. The results were not satisfactory, despite using a uniform interface. Much had to be corrected and supplemented manually. “Despite these sobering lessons, we were able to define important standard processes, develop them to the stage of practical use and implement them in the company within the scope of the pilot project. For that reason, the first approach to the BIM method was an important first step in the direction of digitization for the Klebl Corporate Group,” concludes Heilmeier, looking back to initial experience gained.

How does BIM workflow function in detail?

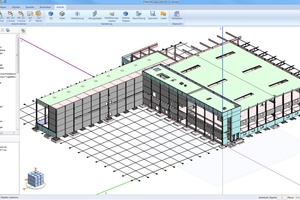

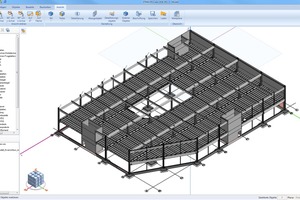

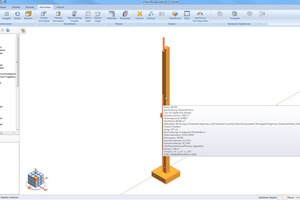

The architecture technical model, if available, is imported per IFC interface (Industry Foundation Classes). In this model, the precast components are designed in the construction-documents phase, taking into consideration all linking points such as joints, supports, connections and embedded parts. Data on the precast components are stored separately as files and, on this basis, reinforcement and formwork drawings are generated. Steel construction drawings, if required, are prepared in much the same form. The planning documentation prepared in this manner, BVBS reinforcement data and 3D models are published on the internal Klebl project platform and shared with all parties involved in the project. The individual architectural, structural and HVAC technical models are merged in collaborative software.

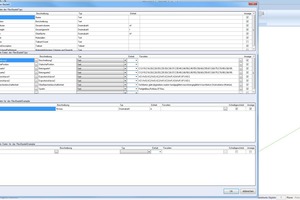

Collation of the technical models is a challenge of a special kind. It begins with uniform specification of a coordinate origin and culminates in the definition of a common standard for developing the model. For merging the models, the Klebl Department for Digital Planning has set up its own collaboration platform. There, the technical models are imported and adapted according to their individual requirements: for example, models with embedded parts, etc. Heilmeier knows the sensitive points: “Owing to the different software programs, we also of course receive different attribute names for descriptions and volumes. These are automatically normalized with the aid of Java scripts based on our Klebl planning guidelines.” The internal BIM workflow is, in addition, supported by project templates and standardized forms made up by us. They simplify the disposition and exchange of information among project participants from planning, production and implementation.

Internal standards ensure smooth processes

Heilmeier is aware of the significance of standards and makes sure that they are observed in the process flow: “Uniform specifications are a prerequisite for well-functioning collaboration – both internally and externally. For this reason, we have introduced a Klebl detailed catalog specifically for structural design and have supplemented it with a design guideline. The breakdown of the model and its components are filed as template files. All this information is made available to the external planners and designers at the beginning of the project.” Despite the change to the 3D design, it became apparent at Klebl that important information, e.g., layout plans was completed only when the model was finalized.

The fact that departments such as precast production and erection need to access this information at an earlier point of time initially caused some problems in the internal process chains. Accordingly, the structure within the technical offices was adapted and special project teams were organized. Now, a project manager prepares surveys as early as possible, enabling the designers to prepare detailed drawings of the individual structural components – with all of that included in one single model to prevent data inconsistencies.

No BIM without the proper tools

Digitization and BIM are implemented with special software tools. Many obstacles had to be overcome in their selection as well, reports Heilmeier: “Because our previously used structural design system was capable only of 2D, and because the manufacturer had ruled out a change to 3D, we had to take a new approach. The good experience we have had with Strakon from Dicad and its quick adaption to BIM were decisive for us, in 2014, to opt for Strakon. Today, 18 colleagues work with this software and plan and design structural precast components with it. Within the Klebl Group, Strakon is the central tool for designing of our structural precast components.” Heilmeier sees essential advantages also in the simple construction of complex precast components and in reduction of the error rate, because the components are designed only once and because changes are automatically matched in all representations.

The “think project!” platform is another BIM tool with which a complete exchange of plans is processed. With the internal Klebl system for production planning and control (PPS), all information relevant to production and erection is acquired – from the dimensions of a component to production planning and finally to erection planning. For the display, coordination and control of the BIM models, Klebl uses the Desite program from Ceapoint, which is linked to the project room and the PPS system over WEB Services. This enables automatic comparison among the systems.

BIM is both opportunity and challenge

“The question of whether or not a company will work in future on the basis of the BIM method has by now been answered by the market. In the face of increasing digitization, BIM, in my opinion, will become an integral part of construction processing – from planning to execution and all the way to operation,” notes Heilmeier, who adds: “Based on the varied and extensive experience that the Klebl Group has gained with the BIM method, it should also be clearly stated that we have still a long way ahead of us. BIM offers both opportunities and risks to all companies. A decisive prerequisite for economically successful implementation of BIM in a company is that everyone within one project and the corporate organization work in accordance with this method. Otherwise, unnecessary additional costs will be incurred.”

According to Heilmeier, further challenges include the integration of many project participants with a great variety of software systems. Despite utilization of standard formats – for example, IFC – error-free data exchange is hardly possible. In addition, and in the opinion of Heilmeier, BIM must be integrated above all into all corporate processes and communications among all parties improved. For this, reason he sees networking of the systems and more intensive communications as a core task for the future, internally and externally.