Loadbearing precast elements delivered for EU project

The objective of the EU project SeRaMCo (Secondary Raw Materials for Concrete Precast Products), which is now nearing completion, is to increase utilization of recycled constituents in concrete construction in practice in the interest of sustainability. Eleven European research partners from science and industry participated in the research project with a total volume of over €7 million, among them the Syspro Group Betonbauteile e.V., by its member Beton-Betz from Kirchardt, in Germany.

The project, promoted by Interreg North-West-Europe with €4.4 million, is led by the Department of Structural Engineering and Building Construction at Kaiserslautern Technical University in Germany. Within the scope of the three-year research program, mixes for recycling concrete were optimized and new applications for loadbearing and non-loadbearing precast elements and other concrete products were developed, which are comparable to conventional products, both in terms of quality and cost efficiency.

Groundbreaking for pavilion of RC concrete in Pirmasens, Germany

The completion of the project was the practical application of innovative precast elements made of recycled constituents in three pilot projects. The Syspro member Beton-Betz delivered the precast elements for two of these projects.

The public had been presented with a prestigious noise barrier on a parking lot on French highway A31, 15 km from the city of Thionville, already in September 2020 with the inscription “Thionville – Porte de France.” The precast elements used are highly innovative, consisting of 100 % recycled aggregate, and thus clearly above the French maximum limit value of 20 %.

Syspro Group supplied loadbearing precast elements for the first time

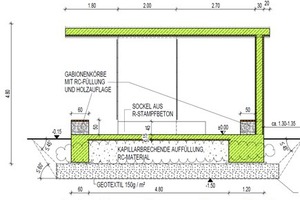

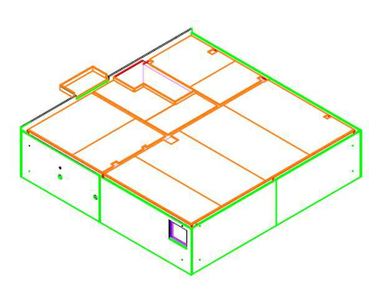

Another practical application of the findings gained from the new project is the planned implementation of a detached, one-story pavilion in Pirmasens, Germany. Near the university campus in that city, the erection of a pavilion is underway on an area of just 5 x 7 m, which can serve both as a place of encounter for young and old and as an attractive stage for music and artists. The open pavilion will consist of several precast slabs with in-situ RC concrete topping (slab elements and double-wall elements) as well as precast foundations.

For this project as well, project-related type-approval (VBG) in accordance with the regional building regulation of the German state of Rhineland-Palatinate was also provided. The type-approval was granted based on the relevant expert opinions and the statements obtained and made available by the Syspro Group. This refers in particular to the use of precast elements made of RC 25/30 concrete, with RC cement and 10 % crushed sand plus 35 % recycled aggregate, which lies above the specifications of the DafStb code of practice. The project was completed by C25/30 in-situ concrete with aggregate category type 1 (max. 35 % vol. content of RC aggregate) in accordance with the DafStb Code of Practice. The official inauguration of the pavilion will therefore demonstrate in an impressive way what is already today possible with precast elements of recycled construction materials.

2. Pilot project on (near) completion of EU project SeRaMCo

Now that the project is nearing completion, the project partners expressed considerable satisfaction. “For us, the Betonwerk-Betz team as member of the Syspro Group, working together with our competent network of European partners signifies considerable enhancement of our corporate expertise. Creating the products for Thionville and Pirmasens within the scope of the EU project SeRaMCo was a real distinction for us. This project has fired our imagination from the very beginning, because we see the knowhow gained in recycling concrete as an opportunity for the future, both for our company and the entire industry. The use of recycled concrete is a major contribution for reducing the ecological footprint,” emphasizes Sascha Meiser, Managing Director of Betonwerk Betz.

Text: Dr.-Ing. Thomas Kranzler