Sponsored project on recycling concrete goes into the practical phase

The EU-sponsored project SeRaMCo – “Secondary Raw Materials for Concrete Precast Products” – began on 15 June 2017 with participation of the SySpro founding member, the company Beton-Betz GmbH, as lead partner. The objective is the “upcycling” of construction waste from concrete, brick, tiles and ceramics: i.e., the conversion of construction waste into new quality products. So far, only 4 % of construction waste is currently being recycled, despite the fact that construction waste represents one third of all European waste – the largest portion of total waste accumulated in the EU. Belgium, France, Germany, Luxemburg and the Netherlands have set the goal of optimizing the reutilization of materials and of preserving natural resources. This confronts the players in the building trade with the challenge of placing their upcycled products on the market.

The main focus is on the development of newer formulations and precast elements. Precast elements, concrete products and cements made of secondary raw materials are planned to be manufactured subject to the requirement that they, in terms of price and quality, are comparable to conventional products and are thus able to make a positive contribution to the economic cycle.

Knowhow acquired at Beton-Betz

The knowhow required for practical application has been gained by Beton-Betz. Concrete residues from the company’s own production can be recycled for reutilization by a special mobile reprocessing plant using three sifters. The sand and particle fractions are stored on the company site and integrated into the production process.

However, the properties of the crushed material deviate from the normative numerical values. This influences the properties of the concrete, in particular the modulus of elasticity as well as the effects of creep and shrinkage. This results from the fact that the newly obtained formulation contains crushed sand that, during recycling, occurs in larger quantities but possesses a very high fineness and was subject to special investigation.

Recycled concrete shows no deviations from normal concrete

Many properties of recycled concrete had already been determined in the laboratory within the scope of the EU-subsidized project. However, little is known about the behavior of floors and walls. Testing in practice is now taking place in the implementation phase.

The first concrete floor slabs made of recycled concrete were manufactured in the autumn of 2018 and exposed to natural weathering in the storage yard of Beton-Betz to determine shrinkage effects on structural components of this kind. After the first winter, no significant differences from normal concrete were in evidence.

Building permit for the first reference project applied for

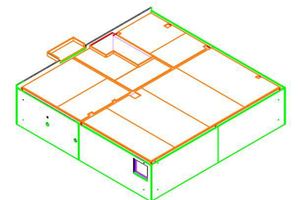

The responsible building authority in Tübingen, Germany, which has extensive experience with recycled concrete, has received an application for a building permit for a residential building to be made of recycled concrete. In the meantime, the permission drawing has been submitted: it specifies the use of recycled concrete for external and interior walls and floor slabs. The structural design must, in particular, verify serviceability: i.e., the modulus of elasticity and creep/shrinkage.

In March 2019, Beton-Betz erected two structural components in a monitoring test, to show differences from normal concrete. On 29 April 2019, the Tübingen Institute for Testing inspected the permanent loading test and is expected to approve the first reference project shortly.